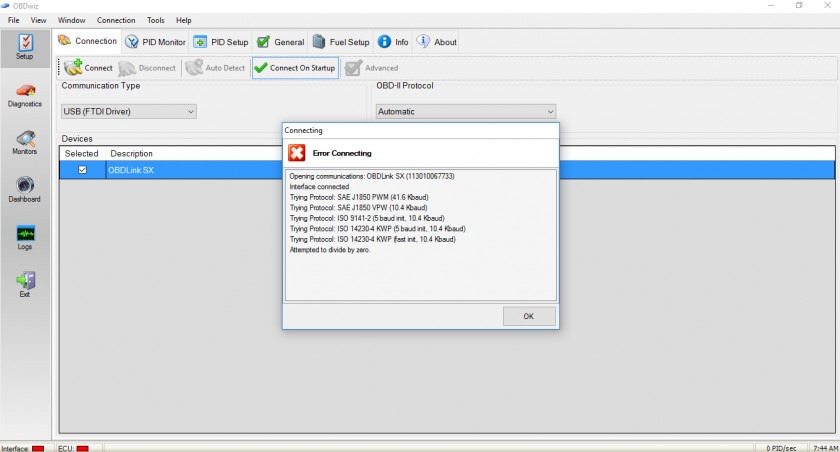

If your scan tool isn’t communicating with your 2004 Mazda MPV, you’re not alone. This is a common issue that can be caused by several factors. This guide will walk you through troubleshooting steps to pinpoint the problem and get your scan tool working again.

Common Causes of Communication Failure

Several issues can prevent a scan tool from communicating with a 2004 Mazda MPV. Here are some of the most frequent culprits:

1. Faulty Scan Tool:

The scan tool itself might be malfunctioning due to hardware or software problems. Try using a different scan tool to rule out this possibility.

2. Damaged OBD-II Port:

The OBD-II port on your Mazda MPV might be damaged or have loose connections. Inspect the port for any bent or broken pins, debris, or corrosion.

3. Wiring Issues:

Damaged or disconnected wires between the OBD-II port and the Powertrain Control Module (PCM) can disrupt communication.

4. Dead or Weak Battery:

A low battery voltage can prevent the scan tool from establishing a connection with the PCM. Ensure your battery is fully charged and in good working condition.

5. Blown Fuse:

A blown fuse related to the OBD-II system or the PCM can cut off power, hindering communication. Consult your owner’s manual to locate the relevant fuses.

Troubleshooting Steps

Here are some tests you can perform to diagnose the problem:

Test 1: Ground Circuit Check (DLC Pin 4 and 5)

- Connect the positive lead of a Digital Multimeter (DMM) to DLC pin 4 and the negative lead to the negative battery terminal. Use jumper wires if necessary, ensuring a direct connection to the battery terminal, not the chassis ground.

- Turn the ignition ON. The voltage drop should be 0.1 volts or less.

- Repeat this test for DLC pin 5.

- Note: A high voltage drop indicates a problem with the ground circuit, preventing the PCM from entering diagnostic mode.

Test 2: PCM Data Signal Check (DLC Pin 2 – Not Applicable to Mazda MPV)

- This test is generally performed to check the data signal from the PCM, but it’s not applicable to the 2004 Mazda MPV.

Test 3: Power Supply to PCM (DLC Battery + Terminal)

- Connect the positive DMM lead to the DLC Battery + terminal and the negative lead to the battery ground terminal.

- The DMM should display the battery voltage. This confirms power is reaching the DLC connector. A low voltage indicates a potential issue with the power supply to the PCM, possibly caused by a blown fuse.

Checking voltage at the DLC connector

Checking voltage at the DLC connector

Test 4: Bus Activity Check (DLC Bias Terminals)

- Connect the positive DMM lead to either DLC bias terminal (typically pins 6 and 14). Connect the negative lead to ground.

- With the ignition ON and no bus activity, BUS+ should read 0V, and BUS- should read 5V.

- With the ignition ON and bus activity present (e.g., trying to communicate with the scan tool), the voltage should fluctuate between 0V and 5V. No fluctuation suggests a lack of communication on the data bus.

Further Considerations

- PCM Failure: In rare cases, a faulty PCM can prevent communication. If all other tests fail, a professional diagnosis might be necessary.

- Fuse Box Inspection: Thoroughly inspect the fuse box (Power Panel) for any blown fuses related to the PCM or the OBD-II system.

If these troubleshooting steps don’t resolve the issue, consult a qualified mechanic specializing in Mazda vehicles for further diagnosis and repair. A professional can use advanced diagnostic equipment to pinpoint the problem and ensure your 2004 Mazda MPV is back in top shape.