A 2005 Mercury Mountaineer exhibiting hard starts, rough idle, and particularly rough idle when in gear often points to fuel system issues. A common diagnostic approach involves using a scan tool to read error codes and monitor fuel trim values. This article will delve into interpreting these readings, specifically focusing on high fuel trim on Bank 2, a common problem in this vehicle.

Understanding Fuel Trim and Bank 2

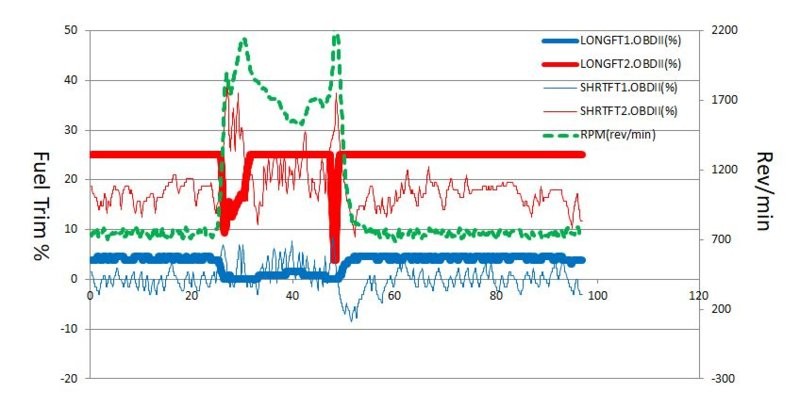

Fuel trim is a crucial engine management parameter that indicates how the engine control module (ECM) adjusts fuel delivery to maintain the ideal air-fuel ratio. A positive fuel trim percentage signifies the ECM is adding fuel, indicating a lean condition. Conversely, a negative fuel trim signifies reduced fuel delivery, indicating a rich condition.

Bank 2 in a V6 or V8 engine refers to the side of the engine opposite Bank 1, typically the driver’s side in the 2005 Mercury Mountaineer. High positive fuel trim on Bank 2, as indicated by consistently high Long Term Fuel Trim (LTFT) and Short Term Fuel Trim (STFT) values, suggests a persistent lean condition on that side of the engine.

Diagnosing High Fuel Trim on Bank 2 in a 2005 Mercury Mountaineer

The original poster (OP) meticulously documented troubleshooting steps, replacing various components, including:

- Spark Plugs and Wires

- Ignition Coil

- Fuel Filter

- Mass Airflow Sensor (MAF)

- Fuel Rail Pressure Sensor

- Intake Manifold Gaskets

- Upstream Oxygen Sensors (both banks)

- EGR Valve

fuelTrimExplorer.JPG

fuelTrimExplorer.JPG

Despite these efforts, the high fuel trim on Bank 2 persisted. The graph shared by the OP clearly illustrates the significantly elevated LTFT2 and STFT2 values compared to Bank 1. This indicates the problem is specific to Bank 2 and not a general fuel delivery issue.

Potential Causes and Further Diagnostic Steps

Several potential causes remain, warranting further investigation:

1. Exhaust Leaks Before the O2 Sensor:

A leak upstream of the Bank 2 oxygen sensor can introduce unmetered air into the exhaust stream, causing a false lean reading. Using a smoke machine to pressurize the exhaust system can help pinpoint leaks.

2. Fuel Injector Functionality:

While the OP cleaned and swapped injectors, verifying proper fuel delivery under operating pressure is crucial. This could involve a professional fuel pressure test and potentially an injector flow test. A clogged fuel injector on bank 2 could be the culprit for the lean condition.

3. Fuel Pressure Issues:

Low fuel pressure, although less likely given the isolated Bank 2 issue, can contribute to a lean condition. While the 2005 Mercury Mountaineer lacks a fuel rail test port, a fuel pressure gauge can be connected using an adapter. A failing fuel pump might struggle to maintain adequate pressure, particularly under load.

4. Vacuum Leaks:

Despite the smoke test, a thorough inspection for vacuum leaks using a propane enrichment test (carefully introducing propane around potential leak points while monitoring fuel trim) can help identify smaller, elusive leaks specific to Bank 2. Focusing on vacuum lines and components connected to Bank 2 is crucial.

5. Mechanical Timing Issues:

While less common, issues with the timing chain or related components on Bank 2 can disrupt engine performance and lead to a lean condition. Verifying proper timing using specialized tools may be necessary.

Conclusion

Diagnosing high fuel trim on Bank 2 in a 2005 Mercury Mountaineer requires a systematic approach, eliminating potential causes one by one. Based on the information provided, focusing on exhaust leaks, confirming proper fuel injector operation under pressure, and a meticulous vacuum leak check specific to Bank 2 are recommended next steps. Addressing these potential issues can lead to resolving the underlying lean condition and restoring optimal engine performance.