A 2005 Dodge Ram 2500 with a 5.9 Cummins diesel engine experienced a significant loss of power and poor shifting. Initial road testing under light load revealed no issues. However, under heavier throttle (3/4 or more), the truck would initially accelerate but then suddenly lose power. The RPMs would remain high, but the engine felt like it was starved of fuel or experiencing excessive exhaust back pressure. The power loss would be temporary; easing off the throttle and reapplying it would briefly restore power before it dropped off again. The transmission shifting problems seemed to be directly related to the engine’s power loss.

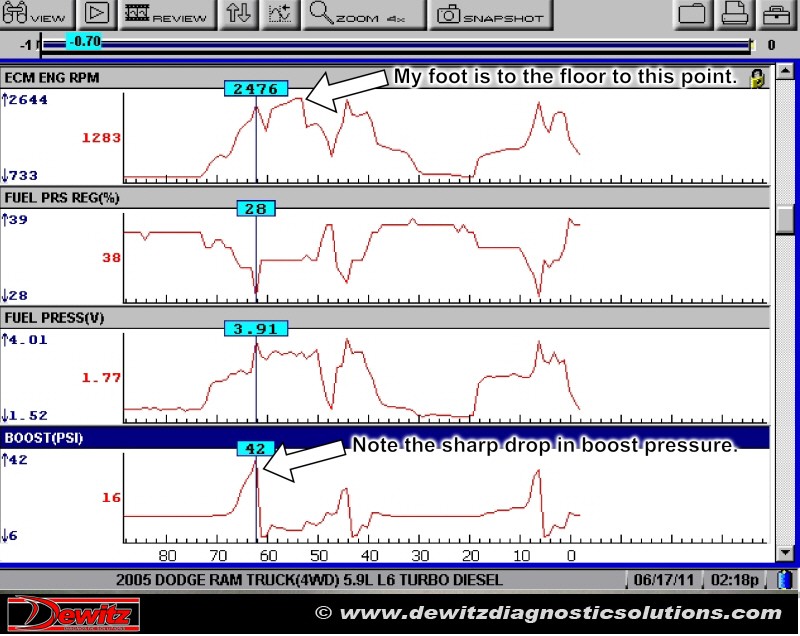

Further analysis using a scan tool, specifically graphing various PIDs (Parameter Identification Data), helped pinpoint the problem. Notably, there were no stored engine codes. The scan tool data revealed normal exhaust back pressure and consistent fuel pressure, ruling out those potential causes. However, the turbo boost pressure showed a dramatic drop coinciding with the power loss. This pointed towards a problem with the turbocharger system.

Several possibilities were considered: Was the Powertrain Control Module (PCM) intentionally reducing turbo boost? Was the turbocharger itself malfunctioning? And if the PCM was involved, why, and to what extent could it control the turbo on this particular engine? Reviewing the scan data further uncovered another clue: the BARO (Barometric Pressure) readings plummeted simultaneously with the power loss. A stable BARO reading is expected since ambient air pressure doesn’t change rapidly. A sudden drop suggested a significant air restriction between the air intake and the BARO sensor.

Inspection of the air filter revealed the culprit: a severely clogged air filter. It was surprising to find an air filter restricted to the point of causing such a drastic power loss. This case highlights the importance of using a scan tool to diagnose 5.9 Dodge 5.9 Scan Tool Issues, especially when dealing with intermittent problems and the absence of error codes. By systematically analyzing live data, the root cause—a simple yet critical component—was identified, saving time and potentially avoiding unnecessary repairs. Using a scan tool to graph data, specifically monitoring parameters like boost pressure and BARO readings, proved crucial in pinpointing the source of the power loss in this 5.9 Cummins engine.