Your cart is currently empty!

Mastering the Secondary Air Test with VCDS

The secondary air injection (SAI) system is crucial for reducing emissions during a cold start. Understanding how to diagnose and troubleshoot issues with this system, particularly using VCDS (Vag-Com Diagnostic System), is essential for any automotive technician. This article focuses on the “secondary air test vcds” and provides a comprehensive guide for performing the test and interpreting the results. Using VCDS, we can pinpoint the root cause of SAI failures, saving time and money on unnecessary repairs. After reading this, you’ll be confident in diagnosing and resolving secondary air injection system problems.

One common issue triggering the check engine light is a malfunctioning secondary air injection system. Diagnosing this can be tricky, but VCDS simplifies the process. The “secondary air test vcds” allows you to activate the SAI pump and valves directly, providing valuable insights into the system’s health. You can access more information on VCDS output tests at vcds output tests beetle awv. This is a great starting point for anyone new to using VCDS.

Understanding the Secondary Air Injection System

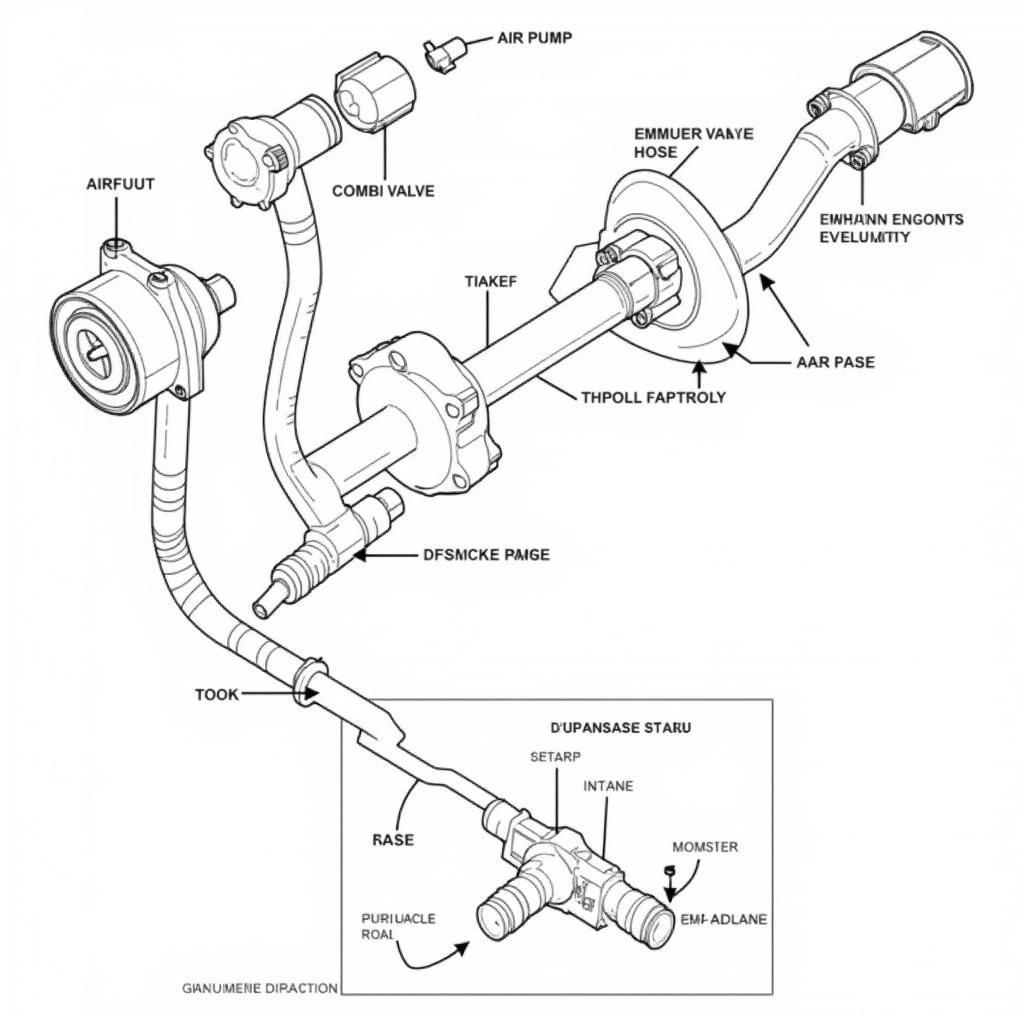

The secondary air injection system injects fresh air into the exhaust manifold during a cold start. This added oxygen helps to quickly burn off unburnt fuel, significantly reducing harmful emissions. A typical SAI system consists of an air pump, a combi-valve, and various hoses and check valves. Any malfunction within these components can trigger a fault code and illuminate the check engine light.

Performing the Secondary Air Test VCDS

Performing the secondary air test with VCDS is a straightforward process. First, connect the VCDS interface to the vehicle’s OBD-II port. Then, launch the VCDS software and select the appropriate vehicle model and engine code. Navigate to the “Engine” module and select “Basic Settings” or “Output Tests” depending on your vehicle’s specific control module. Within these menus, you’ll find the option to activate the secondary air injection pump and related components.

Secondary Air Injection System Diagram

Secondary Air Injection System Diagram

Once activated, listen for the distinct whirring sound of the air pump. Also, observe the readings from the oxygen sensors in the VCDS software. These readings can provide further clues about the system’s functionality. If the pump runs and the oxygen sensor readings respond accordingly, the basic components of the system are likely functioning correctly. You can find more information on various VCDS tests at readiness test vcds.

Interpreting the Results of the Secondary Air Test VCDS

Interpreting the results requires careful observation. If the pump doesn’t run, check the pump’s power and ground connections, as well as its internal fuse. If the pump runs but the oxygen sensor readings don’t change, suspect a blockage in the hoses, a faulty combi-valve, or a stuck check valve.

A common issue is a clogged combi-valve. This valve is responsible for directing airflow into the exhaust manifold. Over time, it can become clogged with carbon deposits, restricting airflow and hindering the system’s effectiveness.

Common Secondary Air Injection System Issues and Solutions

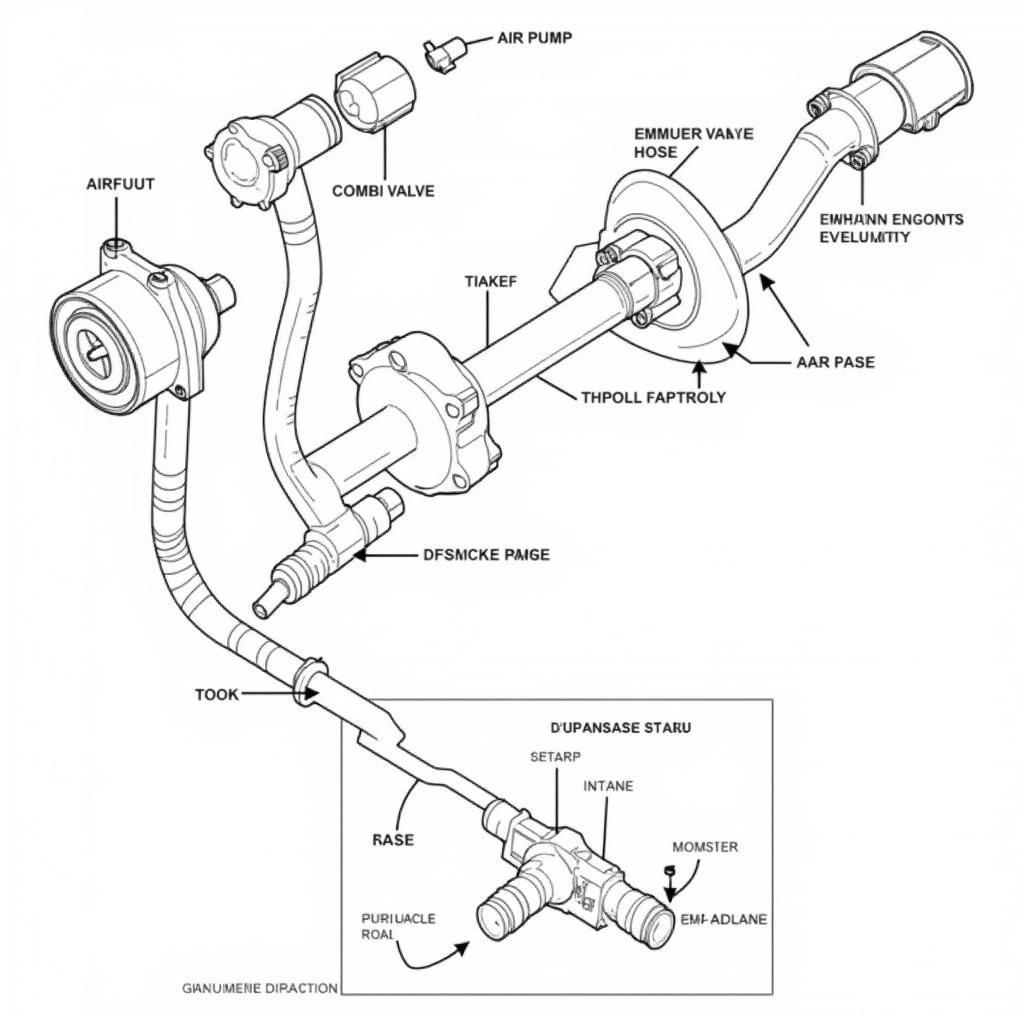

Several common issues can plague the secondary air injection system. Aside from a faulty pump or clogged combi-valve, leaking hoses and malfunctioning check valves can also cause problems. A thorough visual inspection of the system, combined with the VCDS secondary air test, can help pinpoint the culprit.

- Faulty Air Pump: Replace the air pump.

- Clogged Combi-Valve: Clean or replace the combi-valve.

- Leaking Hoses: Replace any damaged or leaking hoses.

- Malfunctioning Check Valves: Replace the faulty check valve.

Checking Secondary Air Injection Hoses

Checking Secondary Air Injection Hoses

“Regular maintenance and timely diagnosis using VCDS can prevent costly repairs down the road,” advises John Miller, a seasoned automotive technician with over 20 years of experience. He adds, “Don’t underestimate the importance of understanding the secondary air injection system, especially when it comes to emissions compliance.”

Why is the Secondary Air Test Important?

The secondary air test is vital for maintaining a healthy emissions system and ensuring your vehicle complies with environmental regulations. A malfunctioning SAI system can not only increase harmful emissions but also lead to decreased fuel efficiency and even engine damage in some cases.

Troubleshooting with VCDS: Ignition Coil Testing

While focusing on the secondary air system, it’s good to know VCDS can diagnose other components too. For instance, vcds ignition coil test allows you to check the functionality of your ignition coils, ensuring optimal engine performance. This is just another example of the versatility and power of VCDS as a diagnostic tool.

Technician Performing VCDS Scan

Technician Performing VCDS Scan

“Knowing how to use VCDS effectively is like having an x-ray vision into your car’s systems,” says Sarah Johnson, a certified master technician. “It empowers you to take control of your diagnostics and make informed repair decisions.”

Conclusion

Mastering the secondary air test with VCDS is essential for any automotive technician. By understanding the system’s operation, performing the test correctly, and interpreting the results accurately, you can effectively diagnose and resolve secondary air injection system issues, ensuring optimal vehicle performance and emissions compliance. For further assistance or personalized guidance, please contact us at VCDSTool. Call us at +1 (641) 206-8880 and our email address: vcdstool@gmail.com, or visit our office located at 6719 W 70th Ave, Arvada, CO 80003, USA.

by

Tags:

Leave a Reply