Your cart is currently empty!

Mastering VCDS Cam Position Sensor Monitoring: A Comprehensive Guide

VCDS cam position sensor monitoring is crucial for maintaining optimal engine performance and diagnosing potential issues. This guide provides in-depth information for car owners, repair shops, and technicians on utilizing VCDS effectively to monitor and troubleshoot camshaft position sensor problems.

Understanding the camshaft position sensor’s role is paramount. It relays vital information to the engine control unit (ECU), dictating fuel injection and ignition timing. A faulty sensor can lead to a myriad of problems, from poor fuel economy to complete engine failure. Learning how to monitor this sensor using VCDS empowers you to identify and address these problems before they escalate. Check out our guide on TDI Timing VCDS.

Why is VCDS Cam Position Sensor Monitoring Important?

Regular VCDS cam position sensor monitoring allows for early detection of potential issues. This proactive approach can save you time, money, and frustration down the road. By identifying discrepancies in the sensor’s readings, you can address the problem before it causes significant damage to your engine.

Identifying Common Camshaft Position Sensor Issues with VCDS

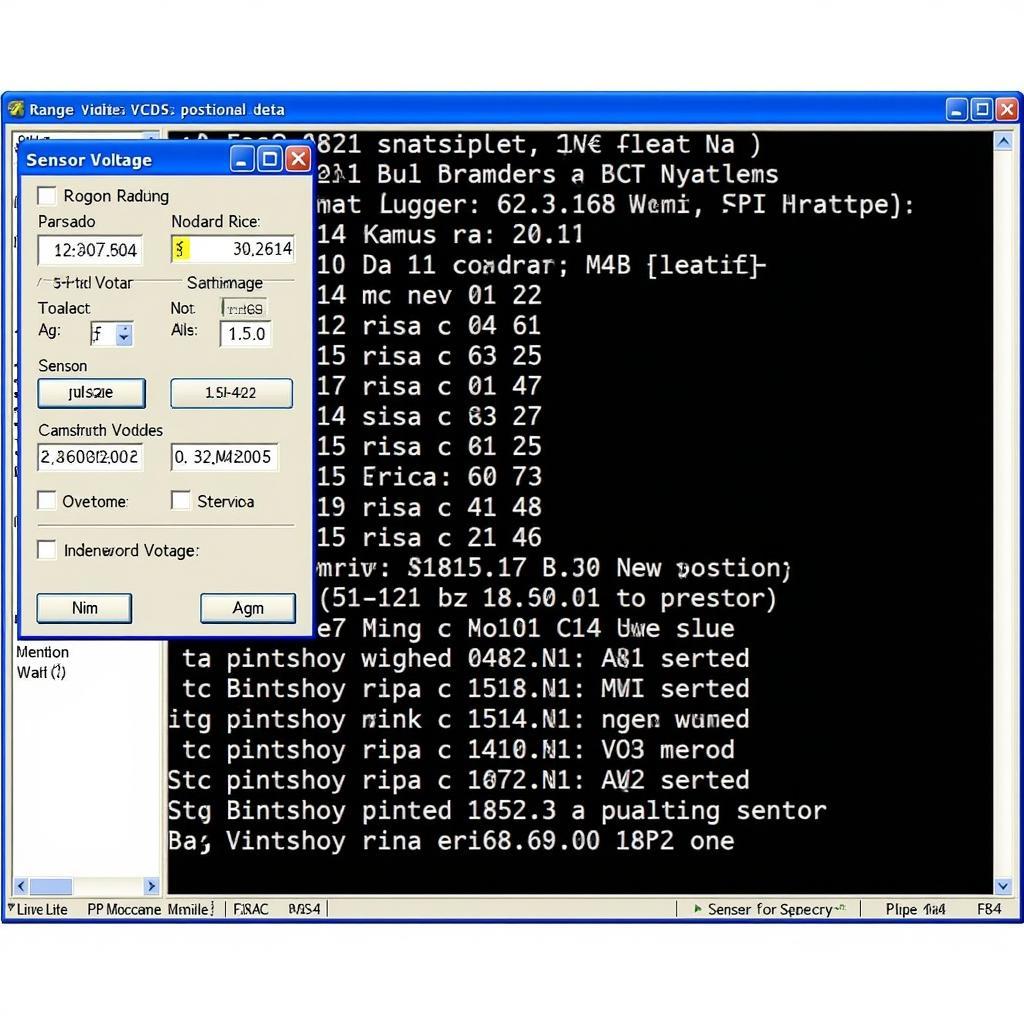

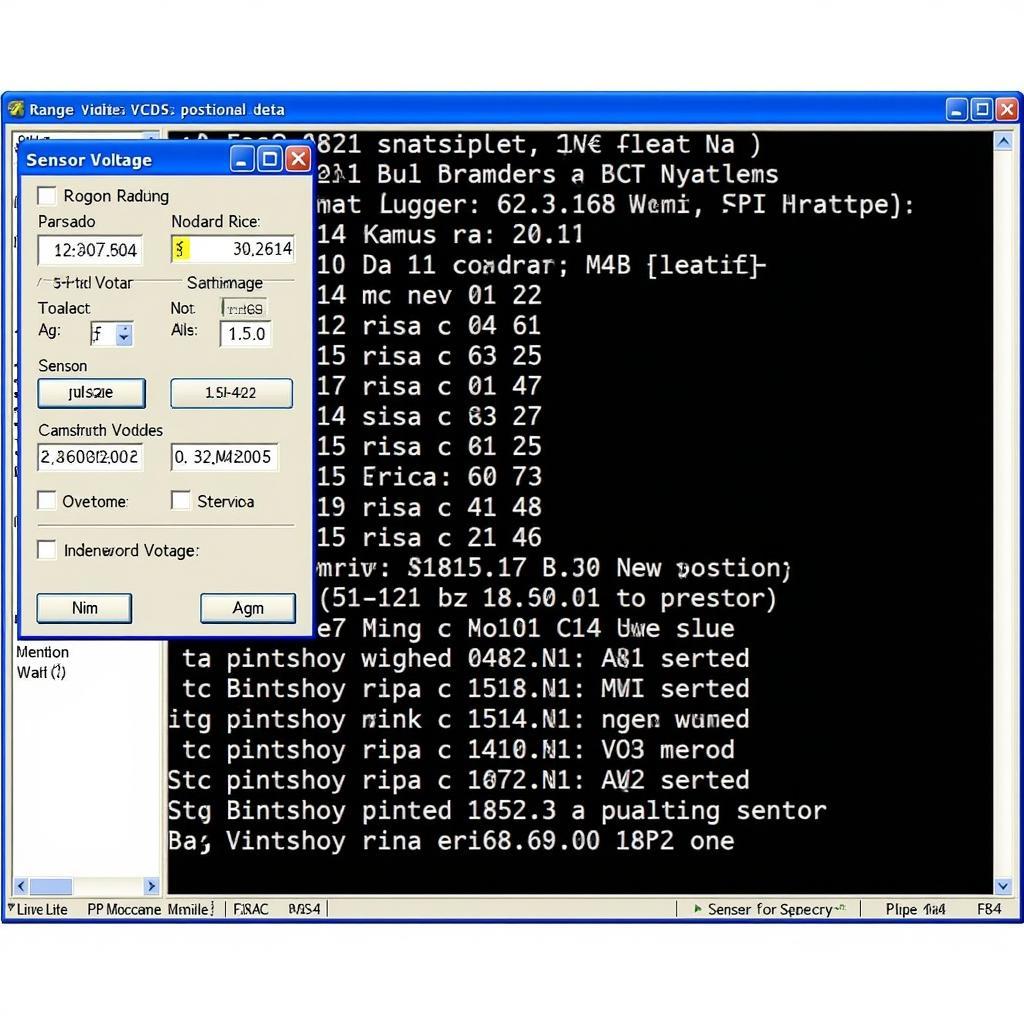

VCDS provides access to live data from the camshaft position sensor, allowing you to observe its behavior in real-time. This is invaluable for diagnosing issues such as intermittent signal loss, incorrect readings, and wiring problems. By comparing the actual values with the expected values, you can pinpoint the source of the problem.

VCDS Camshaft Position Sensor Monitoring Software

VCDS Camshaft Position Sensor Monitoring Software

What if the sensor readings fluctuate erratically? This could indicate a failing sensor or a wiring issue. Conversely, a complete lack of signal usually points to a completely failed sensor or a severed wire.

How to Monitor Your Cam Position Sensor using VCDS

Using VCDS to monitor your cam position sensor is a straightforward process. First, connect the VCDS interface to your vehicle’s OBD-II port. Then, launch the VCDS software and select the appropriate control module for your engine. Navigate to the “Measuring Blocks” section and locate the group related to the camshaft position sensor. You can learn more about specific measurement blocks with our guide on VCDS Timing Meas Block.

Once you’ve found the correct measuring block, observe the live data stream. Pay close attention to any deviations from the expected values. For instance, a significant discrepancy between the camshaft and crankshaft position could indicate a timing issue. Want to understand more about timing issues? Check our article on VCDS Timing Chain Check.

Interpreting VCDS Cam Position Sensor Data

Interpreting the data from VCDS requires some understanding of the expected values. Consult your vehicle’s repair manual for specific tolerances. However, some general rules apply. For example, the camshaft position should always be synchronized with the crankshaft position within a certain range.

Troubleshooting Tips for Camshaft Position Sensor Problems

If you identify a problem with your camshaft position sensor, don’t panic. Start by visually inspecting the sensor and its wiring for any obvious damage. Check for loose connections, corrosion, or frayed wires. If you find any damage, repair or replace the affected components. Sometimes, the problem isn’t the sensor itself but rather a related issue, such as a stretched timing chain.

“A common mistake is assuming the sensor is faulty without thoroughly checking the wiring,” says John Smith, a seasoned automotive diagnostician with over 20 years of experience. “Often, a simple loose connection or corroded wire is the culprit.”

Advanced VCDS Techniques for Cam Position Sensor Diagnosis

For more advanced diagnosis, VCDS offers features like logging data over time and performing output tests. These can help pinpoint intermittent issues that might not be apparent during a static test. Check our guide about VCDS Cam Timing.

“Using VCDS’s logging feature, you can capture data while driving, providing a more comprehensive picture of the sensor’s behavior under real-world conditions,” adds Maria Garcia, a certified master technician specializing in European vehicles. “This is particularly useful for diagnosing intermittent problems.”

In conclusion, VCDS cam position sensor monitoring is a powerful tool for maintaining your vehicle’s health. By understanding how to use this tool effectively, you can diagnose and address potential problems before they become major headaches. For any assistance or questions, feel free to connect with us at +1 (641) 206-8880 and our email address: vcdstool@gmail.com or visit our office at 6719 W 70th Ave, Arvada, CO 80003, USA. We also have a wealth of resources available at vcdstool.com.

FAQ

-

What is a camshaft position sensor?

A camshaft position sensor tells the engine computer the position of the camshaft, which is critical for fuel injection and ignition timing. -

Why is my car misfiring?

A faulty camshaft position sensor can cause misfires due to incorrect timing. -

How do I know if my camshaft position sensor is bad?

Symptoms of a bad sensor can include rough idling, poor fuel economy, and difficulty starting. -

Can I replace a camshaft position sensor myself?

Yes, with basic mechanical skills and the right tools, it’s a manageable DIY project. -

How much does a camshaft position sensor cost?

The cost varies depending on the make and model of your car but typically ranges from $50 to $200. -

What is VCDS?

VCDS is a diagnostic software used to interface with Volkswagen, Audi, Seat, and Skoda vehicles. -

Where can I learn more about using VCDS?

Numerous online resources and forums provide detailed information and tutorials on using VCDS effectively.

by

Tags:

Leave a Reply