Your cart is currently empty!

Mastering VCDS Measuring Blocks for Timing

Understanding your car’s timing is crucial for optimal performance and fuel efficiency. VCDS, or VAG-COM, offers a powerful toolset for diagnosing and adjusting timing issues, and mastering its measuring blocks is key to unlocking its full potential. This article will guide you through using VCDS measuring blocks for timing, whether you’re a car owner, a repair shop owner, or an automotive technician.

Timing is the precise synchronization of various engine components, primarily the crankshaft and camshaft. A slight deviation can lead to reduced power, increased fuel consumption, and even engine damage. VCDS allows you to delve into the intricate details of your car’s timing system, providing valuable data through its measuring blocks. Similar to vcds temperature sensor, this functionality allows you to diagnose issues often invisible to the naked eye.

Decoding the Secrets: What are VCDS Measuring Blocks?

Measuring blocks are essentially data points within the car’s engine control unit (ECU). These blocks contain real-time values related to various engine parameters, including timing. By accessing these blocks through VCDS, you gain insights into the inner workings of your engine.

How to Access Measuring Blocks in VCDS

Accessing these blocks is straightforward: Connect your VCDS interface to your car’s OBD-II port, launch the VCDS software, select your car’s model, and navigate to the “Engine” module. From there, choose “Measuring Blocks – 04” to access the treasure trove of timing data.

Identifying Key Timing Measuring Blocks

Different engine codes have specific measuring blocks related to timing. Consulting your car’s service manual or online resources will help you identify the relevant blocks. Common timing-related blocks often display values for:

- Ignition timing angle

- Camshaft position

- Crankshaft position

- Injection timing

These values, when compared to factory specifications, can pinpoint timing deviations. Checking these sensors can be compared with checking engine speed sensors with vcds because it helps diagnose potential issues within the system.

Interpreting the Data: What Do the Numbers Mean?

Simply seeing the numbers isn’t enough. You need to understand what they represent. For instance, a negative ignition timing angle might indicate retarded timing, while a positive value suggests advanced timing. Comparing these values to the manufacturer’s specifications is essential for accurate diagnosis. This process can be related to using a vcds tdigraph to interpret complex data visually.

Common Timing Issues Revealed by VCDS

Several common timing problems can be identified through VCDS measuring blocks:

- Incorrect camshaft timing: This can be caused by a slipped timing belt or chain.

- Faulty crankshaft position sensor: This sensor provides vital information for timing calculations.

- Worn timing chain tensioner: This can lead to timing variations.

- Issues with the variable valve timing system: This system adjusts the timing based on engine speed and load.

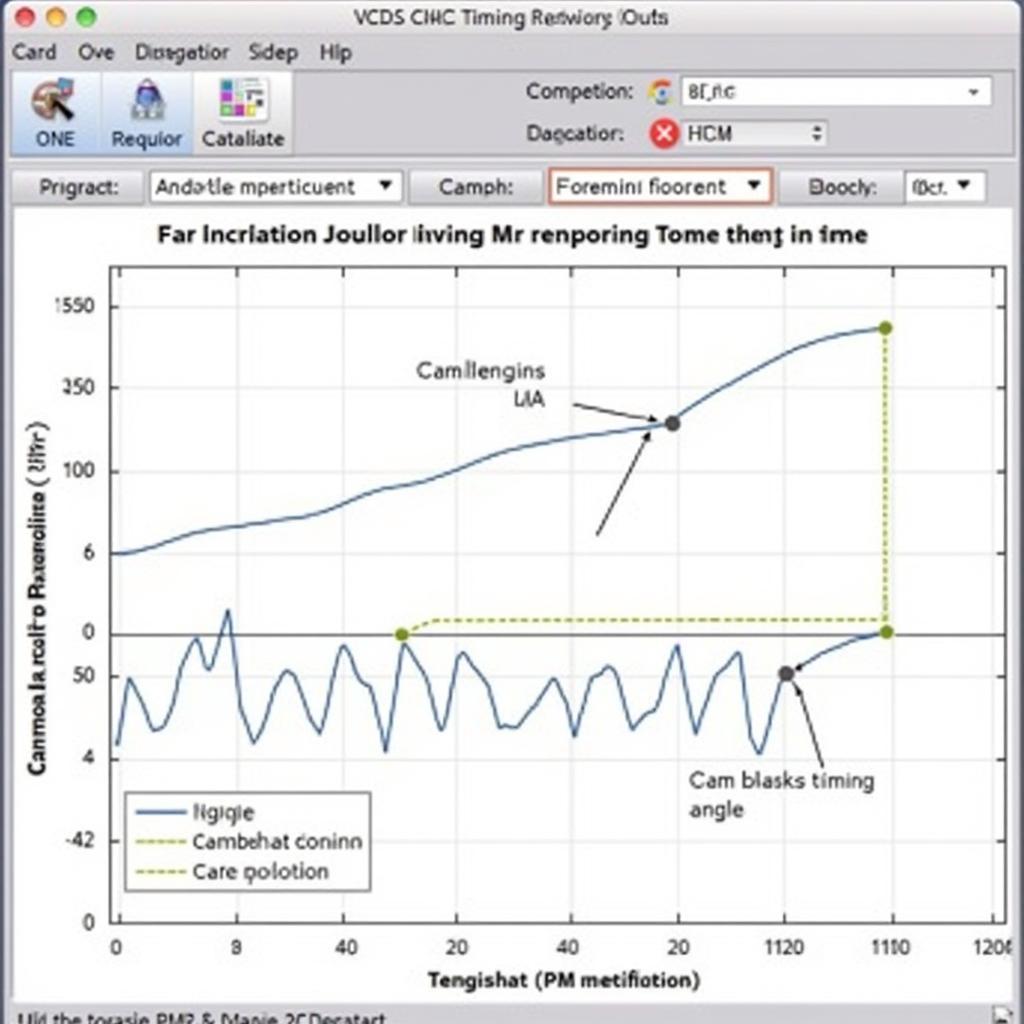

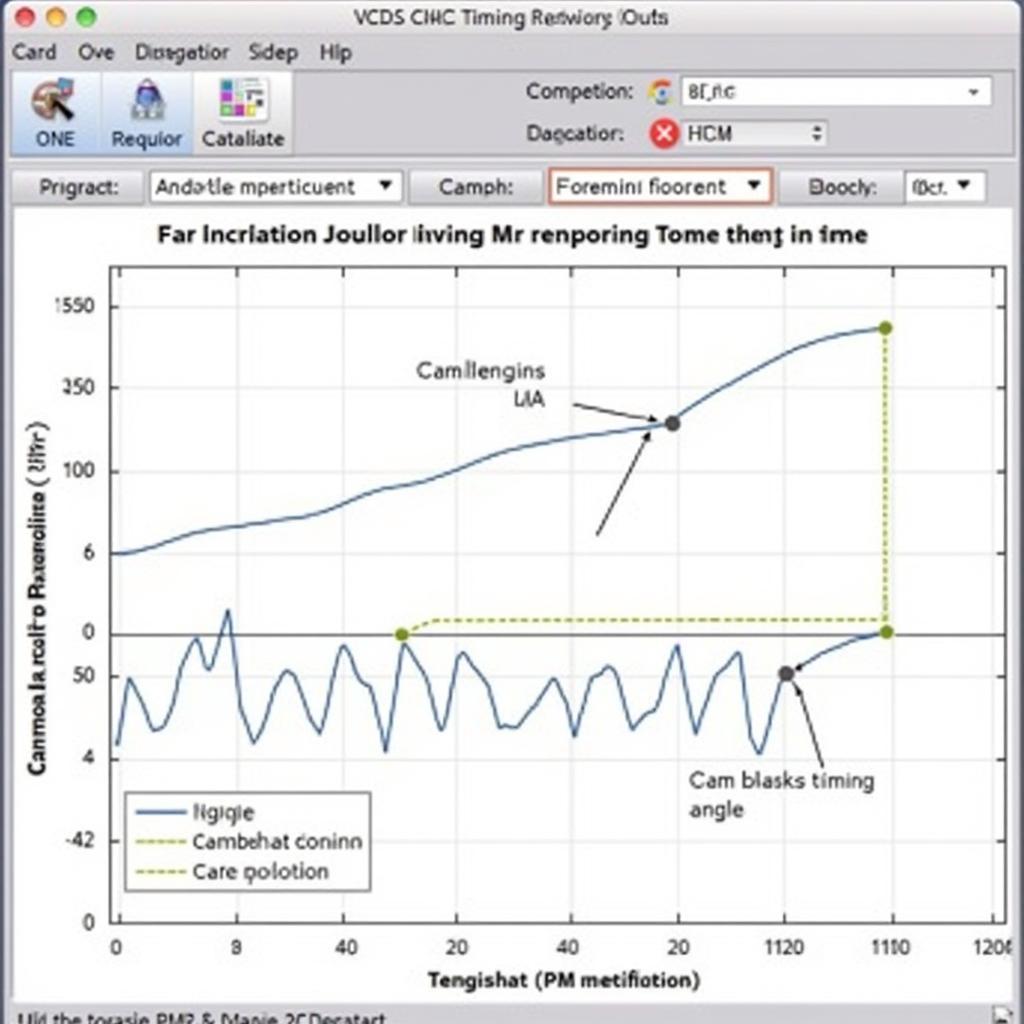

Advanced Techniques: Utilizing VCDS Graphs

VCDS also allows you to graph measuring block data over time, offering a dynamic view of timing fluctuations. This is particularly useful for identifying intermittent timing issues. Similar to vcds graph, using graphs can give a more comprehensive view of the timing data.

Why is graphing timing data beneficial?

Graphing helps visualize trends and fluctuations, providing a more comprehensive understanding of timing behavior under various operating conditions. It allows you to identify intermittent issues that might be missed by simply observing static values. Think of it like an EKG for your engine’s timing.

“Graphing timing data allows you to see the dynamic interplay of various engine parameters,” explains John Smith, a seasoned automotive diagnostics specialist. “This dynamic view is invaluable for pinpointing intermittent timing issues that might otherwise go undetected.”

Analyzing VCDS Timing Graphs

Analyzing VCDS Timing Graphs

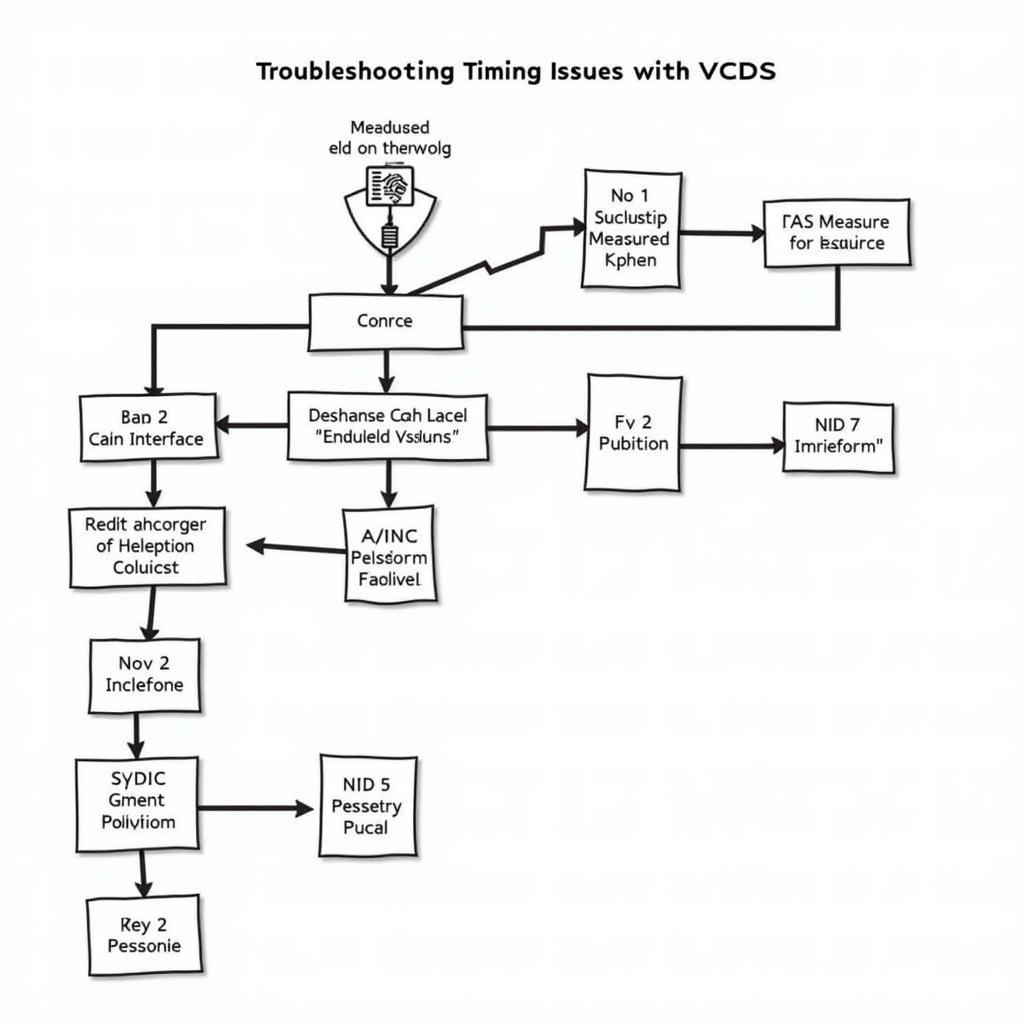

Troubleshooting Timing with VCDS: A Step-by-Step Guide

- Connect your VCDS interface and launch the software.

- Select your car’s model and navigate to the “Engine” module.

- Choose “Measuring Blocks – 04”.

- Identify the relevant measuring blocks for your engine code.

- Compare the displayed values to factory specifications.

- Use the graphing function to visualize timing fluctuations.

“Don’t underestimate the power of VCDS in diagnosing timing issues,” advises Sarah Johnson, a veteran automotive technician. “It’s a game-changer for quickly pinpointing the root cause of timing problems.”

This approach can be particularly helpful for diesel engines, offering insights into injection timing and other TDI-specific parameters. For more information about using VCDS with TDI engines, you can refer to vcds tdi.

VCDS Timing Troubleshooting Steps

VCDS Timing Troubleshooting Steps

Conclusion

Mastering VCDS measuring blocks for timing empowers you to diagnose and address timing-related issues effectively. By understanding how to access, interpret, and utilize this valuable data, you can keep your car running smoothly and efficiently. Remember, precise timing is vital for optimal engine performance. Contact us at +1 (641) 206-8880 and our email address: vcdstool@gmail.com or visit our office at 6719 W 70th Ave, Arvada, CO 80003, USA for further assistance. We’re here to help you navigate the complexities of automotive diagnostics and keep your vehicle in top condition.

FAQ

-

What is VCDS?

VCDS is a diagnostic software for VAG (Volkswagen Audi Group) vehicles. -

How do I access measuring blocks in VCDS?

Go to the “Engine” module and select “Measuring Blocks – 04”. -

What are the common timing-related measuring blocks?

Common blocks include ignition timing angle, camshaft position, and crankshaft position. -

How do I interpret the data from measuring blocks?

Compare the values to factory specifications. -

What are some common timing issues?

Incorrect camshaft timing, faulty sensors, and worn tensioners are common issues. -

How can I use VCDS graphs for timing analysis?

Graphing visualizes timing fluctuations over time. -

Where can I find more information about specific measuring blocks?

Consult your car’s service manual or online resources.

by

Tags:

Leave a Reply