For workshops and fleet managers dealing with Kenworth and Peterbilt trucks equipped with PACCAR MX engines, efficient diagnostics are crucial for minimizing downtime and maximizing productivity. Understanding the diagnostic tools available is the first step in ensuring effective maintenance and repair. In this guide, we delve into the world of PACCAR MX diagnostic solutions, with a focus on the OEM standard, the Davie Scan Tool, and explore user-friendly alternatives like OTR Diagnostics.

PACCAR MX engines, renowned for their performance in Class 8 heavy-duty trucks, come in two main variants:

- PACCAR MX11 Engine: 11-liter, offering 355HP to 445HP.

- PACCAR MX13 Engine: 13-liter, delivering 405HP to 510HP.

When tackling repairs on these sophisticated engines, having the right diagnostic equipment is not just helpful – it’s essential. PACCAR vehicles require specialized tools to communicate effectively with their complex systems and retrieve accurate diagnostic information. Let’s start by understanding the physical connection – the diagnostic port.

Understanding Your PACCAR MX Diagnostic Port

Before connecting any diagnostic tool, it’s vital to locate and identify your truck’s diagnostic port. Important: Always disconnect any Electronic Logging Devices (ELDs) or Y-splitters from the diagnostic port before connecting a scan tool to ensure a stable and reliable connection.

Alt text: Illustration showing the location of the 9-pin diagnostic port in a heavy-duty truck cabin, typically under the dashboard.

The color of your 9-pin diagnostic connector indicates the model year and the communication protocol used:

Green Connector:

- Indicates 2016+ Model Year trucks.

- Utilizes CAN3 communication protocol.

Alt text: Green 9-pin diagnostic connector, indicating CAN3 protocol and used in PACCAR trucks model year 2016 and newer.

Black Connector:

- Indicates 2011-2016 Model Year trucks.

- Utilizes CAN1 communication protocol.

Alt text: Black 9-pin diagnostic connector, indicating CAN1 protocol and used in PACCAR trucks model years 2011 to 2016.

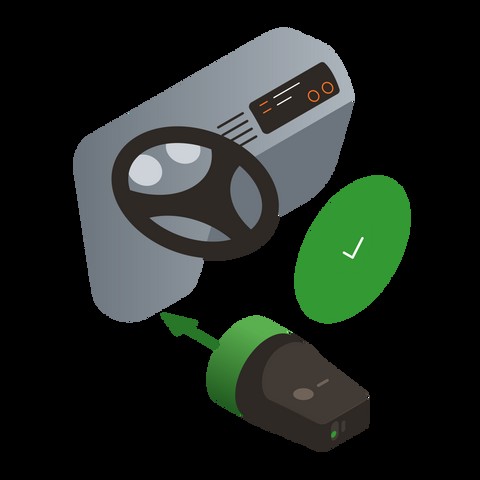

Adapter Requirements for 2016-2021 Models:

For trucks manufactured between 2016 and 2021 with a green diagnostic port, a PACCAR CAN3 to CAN1 adapter is mandatory.

- This adapter bridges the communication gap, converting the CAN3 protocol to CAN1, which is necessary for many diagnostic tools to interface correctly.

- Without this adapter, essential diagnostic commands such as resetting fault codes, EGR derate resets, 5mph derate resets, and forced DPF regeneration will likely fail.

- It’s crucial to note that green diagnostic ports were not used on models prior to 2016, making the adapter specifically relevant for this year range.

2022+ Model Year Trucks:

- For 2022 and newer models, no adapter is needed. You can directly connect your diagnostic tool to the green diagnostic port.

The Essential PACCAR CAN3 to CAN1 Adapter (2016-2021)

Alt text: Image of a PACCAR CAN3 to CAN1 adapter, essential for diagnostic communication on PACCAR MX trucks model years 2016 through 2021 with green diagnostic ports.

For 2011-2016 trucks with a black diagnostic port, the PACCAR adapter is not required, as these models utilize the CAN1 protocol directly.

Important Note: 2016 model year trucks can be equipped with either a black or a green diagnostic port, so always check the port color to determine adapter needs.

With the connection aspects clarified, let’s explore the diagnostic software options available, starting with a simplified solution and then moving to the comprehensive OEM Davie scan tool.

OTR Diagnostics: Streamlining PACCAR MX Diagnostics

For users seeking a straightforward diagnostic experience without the complexities of traditional software and hardware, OTR Diagnostics offers an intuitive app-based solution.

Key Features of OTR Diagnostics for PACCAR MX

OTR Diagnostics is designed for versatility and ease of use specifically for PACCAR MX equipped trucks, offering a range of essential diagnostic and maintenance functions:

- Fault Code Management:

- Read Active/Inactive Fault Codes: Quickly identify current and past issues.

- Detailed Fault Code Information: Provides comprehensive explanations of fault codes, including SA/SPN/FMI/OEM P-code numbers.

- Troubleshooting Guidance: Offers direction on where to investigate the root cause of fault codes.

- Possible Fixes: Suggests potential component replacements or areas to check to resolve the issue.

- Fault Code Count Tracking: Monitors the frequency of fault code occurrences, crucial for diagnosing intermittent problems.

- Fault Code Reset: Clear check engine lights and other indicators on Kenworth or Peterbilt trucks.

- Derate Reset Functions:

- DEF Derate Reset (5mph Aftertreatment Derate): Resets the system to restore normal driving speed, allowing movement to a safe location or repair facility.

- EGR Derate Reset: Disables EGR-related derates triggered by the P1495 fault code (power derate), which activates after the P1496 fault code has been active for over 10 hours. Effective after addressing the underlying P1496 issue.

- DPF Management:

- Install New DPF Function: Deactivates differential pressure-based diagnostics during the DPF degreening process after a new DPF installation, preventing false DTCs.

- Install Cleaned DPF Function: Resets the aftertreatment ECU ash level counter when a cleaned DPF is reinstalled.

- DEF System Maintenance:

- Reset DEF Purge Counter: Resets the counter for SCR/DEF pump module purges after emission aftertreatment system repairs.

- Forced DPF Regeneration: Initiate DPF regeneration to clear soot buildup and maintain optimal aftertreatment system performance. The app tracks regeneration time and stores it in history for monitoring.

- Live Data Monitoring: Access real-time data from engine and aftertreatment systems to aid in troubleshooting and fault code diagnosis.

- History Tracking:

- Fault Code History: Logs all active and inactive fault codes, enabling pattern analysis and frequency tracking.

- Command History: Records regen times and frequencies, along with other executed commands, providing a timeline of diagnostic and maintenance actions.

- Vehicle Information: Integrated VIN decoder for accessing comprehensive vehicle-specific information.

- Offline Mode: Provides access to essential functions even without an internet connection for up to 14 days, ensuring diagnostic capability in remote areas.

Real-World Connection: 2018 Peterbilt 587 Example

Connecting to a truck like a 2018 Peterbilt 587 with OTR Diagnostics is designed to be user-friendly.

Equipment Needed for OTR Diagnostics

- OTR Diagnostics App: Available for download on Android and iOS devices.

- OTR Diagnostics Subscription: Provides access to the diagnostic functionalities.

- OTR Link – Mini Adapter: The hardware interface connecting the mobile device to the truck’s diagnostic port.

- OTR Professional Adapters: Includes necessary adapters like the PACCAR MX and Volvo/Mack adapters for broad compatibility.

OTR Diagnostics Costs

- OTR Diagnostics Pro Subscription: Approximately $600 annually.

- OTR Link + OTR Professional Adapters: A one-time fee of around $200.

- Total Estimated Setup Cost: Approximately $800 initially, followed by $600 annual subscription renewals.

Advantages of OTR Diagnostics

- User-Friendly App: Intuitive and easy to navigate, enabling quick connection and access to vital truck data.

- Affordability: Significantly more cost-effective compared to traditional dealer-level scan tools.

- Portability: Minimal hardware requirements make it highly portable and convenient for field use.

- Offline Functionality: Ensures usability in areas with limited or no internet connectivity.

- Broad Coverage (Pro Subscription): Access to diagnostics across various makes and models within the OTR Diagnostics coverage range.

Limitations of OTR Diagnostics

- Mobile/Tablet Only: Currently available only as a mobile app, with no desktop version.

- No Reprogramming Capabilities: Does not support ECU reprogramming or software updates, such as vehicle speed parameter adjustments, which require tools like Davie 4.

Davie 4: OEM-Level Diagnostic Software for PACCAR MX

For comprehensive, dealer-level diagnostics and deeper system access, Davie 4 stands as the OEM software solution for PACCAR engines.

Alt text: Screenshot of the Davie 4 diagnostic software interface, showcasing its professional and detailed layout for PACCAR vehicle diagnostics.

Davie 4 provides extensive access to all modules and subsystems linked to the PACCAR engine, offering a complete diagnostic overview.

Alt text: Davie 4 software interface displaying a list of connected modules including PCI, EAS-4, CMP, MSM, MSB1, RHS, TCM, and VECU, highlighting its comprehensive system coverage.

Modules Typically Accessible via Davie 4:

- PCI (PACCAR Common Rail Injection): Engine Control Module (ECM)

- EAS-4 (Emission Aftertreatment System): Aftertreatment Control System

- CMP (Chassis Module Primary)

- MSM (Master Switch Module)

- MSB 1 (Multiplexed Solenoid Bank 1)

- RHS (Right Hand Steering Column Switch)

- TCM (Transmission Control Module)

- VECU (Vehicle Electronic Unit)

Alt text: Closer view of the Davie 4 software interface, emphasizing the depth of diagnostic information and control available for PACCAR MX engines.

Benefits of Using Davie 4 Software

- Dealer-Level Access: Unrestricted access to all diagnostic functions, commands, and in-depth system information for engine and aftertreatment systems.

- Online History Storage: Cloud-based storage of diagnostic history for record-keeping and trend analysis.

- Online Programming: Enables ECU reprogramming and software updates for engine and related modules.

- PACCAR Report Viewer: Access to detailed PACCAR specific reports and data.

Limitations of Davie 4 Software

- High Cost:

- Software licenses can exceed $3000 per computer, with annual renewal fees around $1700.

- PACCAR Specific: Primarily designed for PACCAR MX engines and aftertreatment systems, with limited or no support for other vehicle systems or makes (requires separate PACCAR ESA for chassis modules).

- Purchase Access Restrictions: Acquiring software licenses can be challenging and often restricted to authorized dealers or large fleets.

- Laptop-Based: Limited to laptop installation, lacking the portability of app-based solutions.

- Functionality Tiers: Features and functions are tiered based on Davie 4 license levels (Basic, Standard, Master, Admin), with full functionality often requiring higher-tier, more expensive licenses.

- Engine Family Limitation: Specifically for PACCAR MX11 and MX13 engines. PACCAR PX series engines (PX7, PX9) require Cummins INSITE software.

- Internet Dependency: Reliant on a stable internet connection for certain features, functions, and vehicle connectivity.

- Complexity and Navigation:

- Steep learning curve, often requiring specialized training to effectively utilize the software.

- Complex menu structures and function locations can be time-consuming to navigate.

- Time-Consuming Operation: Starting the program and establishing vehicle connection can be lengthy, sometimes taking up to 20 minutes per truck for full connectivity.

- Limited Technical Support: Troubleshooting connectivity or software issues often relies on user expertise, with limited robust technical support from PACCAR. CAN bus communication errors, for example, can be challenging to resolve without specialized knowledge.

Choosing the Right Davie Scan Tool or Alternative

PACCAR MX diagnostic tools, whether it’s the comprehensive Davie scan tool or user-friendly alternatives like OTR Diagnostics, are vital for maintaining efficient operations when working with PACCAR MX powered trucks.

Many repair shops and fleets find value in utilizing a combination of diagnostic tools to ensure comprehensive coverage and redundancy. Having multiple tools at your disposal can act as a backup, ensuring continuous vehicle uptime and efficient diagnostics in various situations.

Until next time, stay safe and keep those trucks rolling! 👋