Your cart is currently empty!

Decoding the Oil Level Sensor with VCDS

The oil level sensor, a crucial component in modern vehicles, can sometimes throw a wrench in the works. Understanding how to diagnose and troubleshoot these issues, particularly using VCDS (Vag-Com Diagnostic System), is essential for any car owner, mechanic, or automotive technician. This article delves into the intricacies of using oil level sensor vcds to pinpoint and resolve oil level sensor problems.

The oil level sensor is responsible for providing accurate readings of the engine oil level. This information is displayed on the dashboard, allowing drivers to monitor the oil level and ensure sufficient lubrication for the engine. A malfunctioning sensor can lead to inaccurate readings, potentially causing serious engine damage if left unaddressed. Using VCDS, a powerful diagnostic tool, allows you to go beyond the basic dashboard warning lights and get a detailed look at the sensor’s performance.

Why is VCDS Essential for Oil Level Sensor Diagnosis?

VCDS provides access to the car’s control modules, including the one responsible for the oil level sensor. It allows you to read fault codes, view live data, and perform output tests, giving you a comprehensive understanding of the sensor’s operation. A simple dashboard warning light might just tell you that there’s a problem, but VCDS can tell you what the problem is.

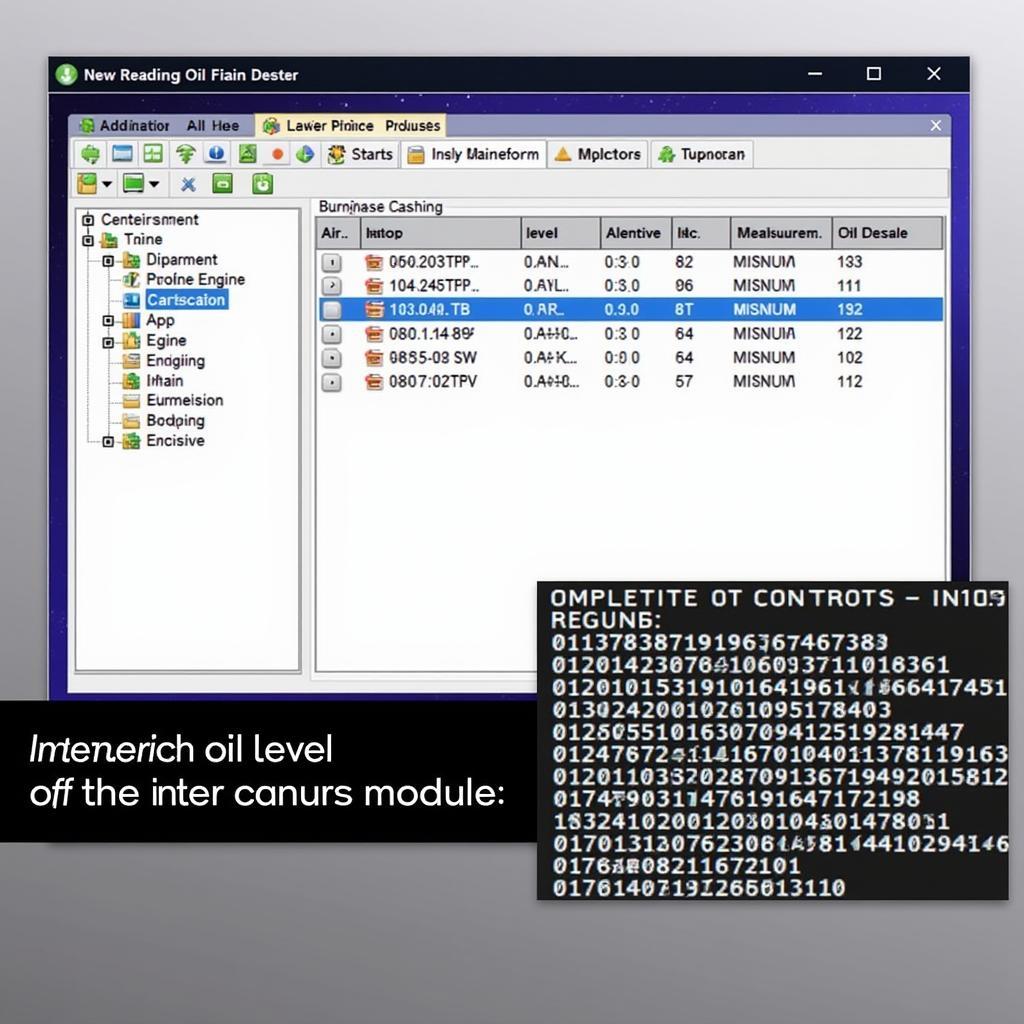

Reading Oil Level Sensor Data with VCDS

Reading Oil Level Sensor Data with VCDS

How to Use VCDS to Diagnose Oil Level Sensor Problems

Using VCDS to diagnose an oil level sensor problem is a relatively straightforward process. First, connect the VCDS interface to your car’s OBD-II port. Next, launch the VCDS software on your computer and select the appropriate control module for your vehicle. Navigate to the oil level sensor data block, which will vary depending on the car model. Here you can view live data from the sensor, including the measured oil level. Comparing this data to the actual oil level, checked manually with the dipstick, can help identify a faulty sensor.

Common Oil Level Sensor Issues and Solutions

Several common issues can plague oil level sensors. Wiring problems, sensor damage, or even software glitches can all lead to inaccurate readings. VCDS can help pinpoint the culprit. For example, if the live data in VCDS shows a constantly fluctuating oil level, even when the engine is off, it could indicate a wiring problem or a faulty sensor itself.

What are the Symptoms of a Faulty Oil Level Sensor?

Symptoms of a faulty oil level sensor can include an illuminated oil warning light, inaccurate oil level readings on the dashboard, or even a low oil level warning despite the oil level being correct. Ignoring these warnings can lead to severe engine damage due to insufficient lubrication.

“Using VCDS is like having X-ray vision for your car,” says automotive expert, David Miller. “It allows you to see beyond the surface and understand exactly what’s happening within the complex systems of your vehicle.”

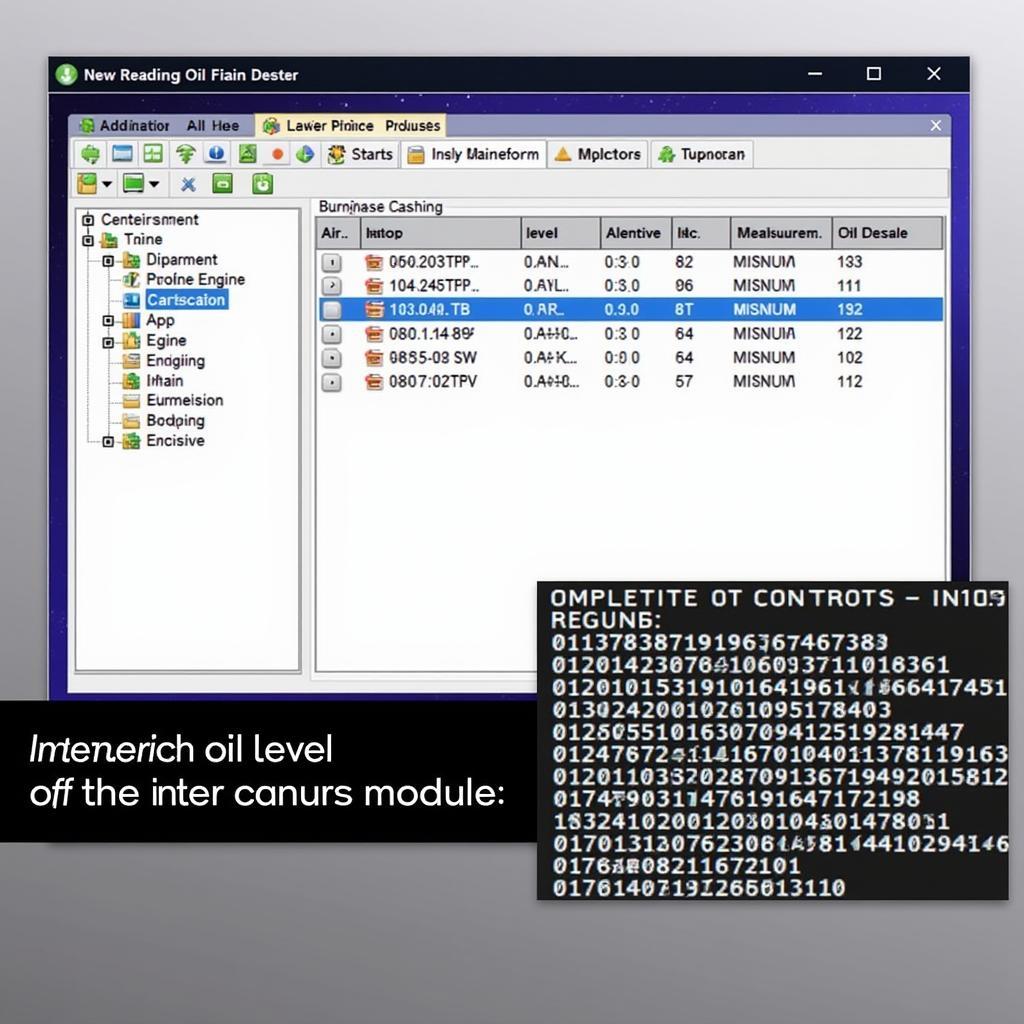

Interpreting VCDS Fault Codes for Oil Level Sensors

VCDS can also provide specific fault codes related to the oil level sensor. These codes provide valuable clues about the nature of the problem. For instance, a specific code might indicate a short circuit in the sensor wiring or a faulty sensor ground connection. Consulting a VCDS fault code database can help decipher these codes and guide the troubleshooting process.

“Don’t just throw parts at the problem,” advises Sarah Johnson, a seasoned mechanic. “Use VCDS to diagnose the issue accurately and avoid unnecessary replacements.”

Troubleshooting Oil Level Sensor Issues with VCDS: A Step-by-Step Guide

- Connect VCDS: Connect the VCDS interface to your car’s OBD-II port and launch the software.

- Select Control Module: Select the appropriate control module for your vehicle (usually the engine control module).

- Access Oil Level Sensor Data: Navigate to the oil level sensor data block within the selected module.

- Analyze Live Data: Observe the live data from the sensor, comparing it to the actual oil level checked manually.

- Check Fault Codes: Scan for fault codes related to the oil level sensor and consult a database for their meanings.

- Perform Output Tests (if applicable): Some VCDS versions allow output tests on the sensor, which can help pinpoint wiring issues.

In conclusion, using oil level sensor vcds empowers car owners, mechanics, and technicians to diagnose and troubleshoot oil level sensor problems effectively. VCDS provides the necessary insights to identify the root cause of the issue, avoiding guesswork and potentially costly repairs. By understanding how to use this powerful diagnostic tool, you can keep your car running smoothly and avoid the headaches associated with oil level sensor malfunctions. Contact us for further support at +1 (641) 206-8880 and our email address: vcdstool@gmail.com or visit our office at 6719 W 70th Ave, Arvada, CO 80003, USA. You can also visit our website at vcdstool.

FAQ

- What is VCDS? VCDS is a diagnostic software and hardware combination used for Volkswagen, Audi, Seat, and Skoda vehicles.

- Where can I purchase VCDS? You can purchase VCDS from authorized retailers or directly from Ross-Tech, the developers of the software.

- Can I use VCDS on other car brands? VCDS is specifically designed for VAG vehicles (Volkswagen, Audi, Seat, and Skoda).

- Is VCDS easy to use? While VCDS offers advanced functionality, it can be user-friendly with some basic understanding and practice.

- What if I don’t understand the fault codes? Many online resources and forums provide explanations and troubleshooting tips for VCDS fault codes.

- Can VCDS fix the problem itself? VCDS is a diagnostic tool; it doesn’t fix the problem itself, but it guides you towards the correct solution.

- What if I still have problems after using VCDS? If you are still having issues after using VCDS, it is recommended to consult a qualified automotive technician.

by

Tags:

Leave a Reply