The concept of modular vehicle wrapping, essentially creating a wrap from separate pieces rather than a single sheet, has existed for decades. Long before the advent of digital printing and the term “wrapping” itself, techniques were employed to overcome the challenges of applying vinyl to complex curves and recesses. These methods involved strategically cutting the vinyl to prevent failure in recessed areas.

Early Techniques for Contour Cutting Vinyl

Three primary methods were used:

Post-Heating Single Cut: After applying and heating the vinyl, a single, light cut was made around the deepest point of a recess. If the vinyl started to lift, the cut would open slightly, revealing a thin line of the vehicle’s color underneath. This minimized visual disruption.

The “Bridge” Technique: This involved applying vinyl across a recess without conforming it to the depth. After installation, a precise cut was made along the edge of the recess, removing the excess vinyl “bridge.” The result mimicked the look of a modular wrap.

The Folded Bridge: Similar to the bridge technique, only one side of the bridge was cut, allowing the remaining vinyl to be folded into the recess, further reducing the visible gap. This created a cleaner finish.

These manual techniques demonstrate that modular wrapping, in essence, predates 3D scanning technology. While these methods might seem rudimentary compared to modern technology, they achieved similar results without specialized equipment.

3D Scanning: A Modern Approach

While traditional techniques remain viable, 3D scanning offers significant advantages, especially for complex projects. Modern 3d Scanning Tools For Tablets provide a precise digital model of a vehicle’s surface, allowing for accurate pre-cutting of vinyl pieces. This minimizes waste, reduces installation time, and enables intricate designs that might be impossible with manual methods.

Specifically, 3D scanning excels in applications like:

- Chevron Kits: Creating precise, pre-cut chevron patterns for emergency vehicles.

- Vehicle-Specific Graphics: Designing and applying complex graphics tailored to the contours of a particular vehicle model.

- Fleet Work: Streamlining the process of applying consistent graphics across multiple vehicles.

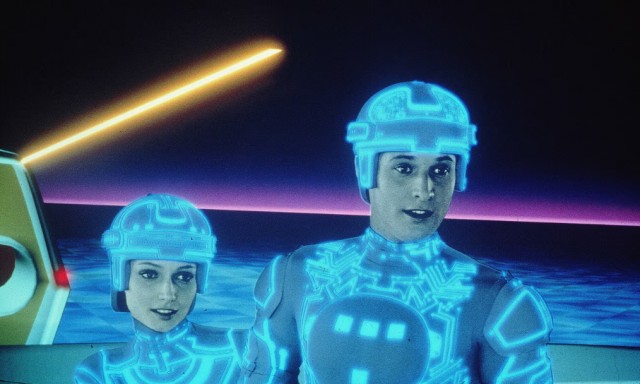

alt text describing image of a car with a tron-like pattern demonstrating modular wrapping

alt text describing image of a car with a tron-like pattern demonstrating modular wrapping

Considering the Investment in 3D Scanning

Investing in 3D scanning tools for tablets represents a significant financial commitment. A complete setup, including software and hardware, can range from £10,000 to £15,000. While the initial cost is substantial, the increased efficiency, reduced material waste, and ability to take on more complex projects can provide a strong return on investment for businesses specializing in vehicle graphics and wraps. However, for smaller operations or those focusing on simpler projects, traditional techniques combined with readily available pre-cut kits might be a more cost-effective solution.

Conclusion

While 3D scanning tools for tablets offer powerful capabilities for modern vehicle wrapping, it’s important to remember that the fundamental principles of modular wrapping have existed for much longer. The decision of whether to invest in this technology ultimately depends on the specific needs and scale of a business. Carefully weighing the cost against the potential benefits is crucial for making an informed decision.