Encountering an ABS (Anti-lock Braking System) fault code can be concerning for any vehicle owner. Understanding what these codes mean and how to address them is crucial for maintaining vehicle safety and performance. Fault codes like C1140 and U1000, often related to the ABS actuator and electrical control unit, can indicate a range of issues from minor electrical glitches to more significant component failures. While some basic checks can be performed, diagnosing ABS problems effectively often requires specialized tools, particularly an Abs Fault Code Scan Tool.

Let’s delve into understanding these fault codes and when utilizing an abs fault code scan tool becomes essential. In many modern vehicles, including both Rear-Wheel Drive (RWD) and All-Wheel Drive (AWD) models, the ABS system architecture is largely unified. This means similar diagnostic approaches apply across different drive configurations.

The DTC (Diagnostic Trouble Code) C1140 specifically points towards a malfunction within the actuator relay of the ABS actuator and electric control unit. This code can be logged as either “PAST” or “CRNT” (CURRENT). Determining this status is where a diagnostic scan tool, ideally an abs fault code scan tool, becomes invaluable. A tool like a CONSULT scan tool, commonly used by service departments, can differentiate between a temporary, resolved issue (PAST) and an ongoing problem (CRNT).

If an abs fault code scan tool indicates a “PAST” C1140 code after running a DTC confirmation procedure, it suggests the fault was transient and no further action is immediately needed. However, a “CRNT” status signifies a persistent issue. Potential causes for a current C1140 fault can include:

- Faulty or loose wiring harness or connector at the ABS actuator and electric control unit.

- Malfunction within the ABS actuator and electric control unit itself.

- Problems within the ABS actuator and electric control unit power supply system.

- A blown fuse related to the ABS system.

- A damaged fusible link.

- In rare cases, a low battery voltage.

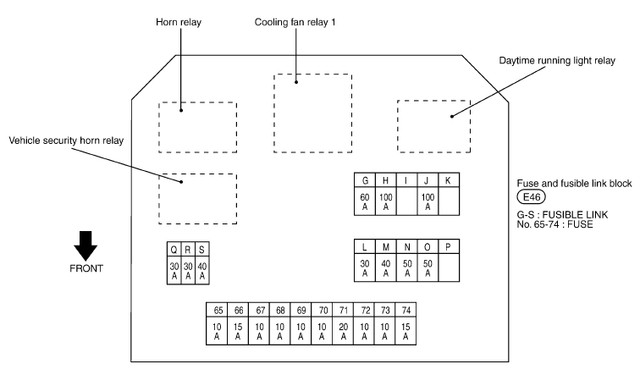

Image depicting the Fuse and Fusible Link Box, highlighting potential areas for inspection related to ABS fault codes.

Fusible links, specifically “L” (30A) and “N” (50A) located in the Fuse and Fusible Link Box, protect the ABS actuator and electric control unit. While less likely, these should be checked. Similarly, while a battery issue is less probable, ensuring proper battery voltage is a basic preliminary step.

If fusible links are intact, further investigation requires checking the power supply and ground circuits to the ABS actuator and electric control unit, as well as the harness connector pin terminals. If these checks yield no issues, the unfortunate conclusion may be that the ABS actuator and electric control unit itself requires replacement.

It’s critical to approach ABS system diagnostics with caution. Working on brake control systems is not recommended for inexperienced individuals. Maintenance and repair of ABS systems should ideally be entrusted to qualified mechanics who possess the necessary expertise and tools, including specialized abs fault code scan tools. While visual inspection of connectors for obvious damage is reasonable, in-depth diagnosis necessitates professional equipment. The ABS actuator and electric control unit is typically located in the engine bay, often near the brake fluid reservoir and master cylinder.

Image illustrating the location of the ABS actuator and electric control unit in a vehicle, emphasizing components relevant to ABS fault code diagnosis.

Another common ABS related DTC is U1000. This code signals a communication interruption within the Controller Area Network (CAN) gateway exceeding 2 seconds. This interruption could be temporary, or it might indicate a recurring communication fault within the CAN network itself if the code persists after restarting the vehicle’s ignition. Again, accurately diagnosing a U1000 code necessitates an abs fault code scan tool capable of reading network communication data and pinpointing the source of the interruption.

In conclusion, while some preliminary visual checks are possible, effectively diagnosing and resolving ABS fault codes like C1140 and U1000 generally requires the use of a professional abs fault code scan tool. These tools provide the detailed diagnostic information needed to accurately identify the root cause of the problem, ensuring safe and effective repairs to your vehicle’s critical Anti-lock Braking System. For any ABS related issues, consulting a qualified mechanic equipped with the appropriate diagnostic tools is always the recommended course of action.