Diagnosing fuel system issues is crucial for maintaining your vehicle’s performance and fuel efficiency. One common concern is fuel pressure, and with the advancement of automotive technology, many car owners and mechanics wonder: Can You Check Fuel Pressure With A Scan Tool? This guide will explore the capabilities of scan tools in fuel pressure testing, and when you might need to rely on traditional methods.

Understanding Fuel Pressure and its Importance

Fuel pressure is the force at which fuel is delivered from the fuel pump to the engine’s fuel injectors. Correct fuel pressure is vital for optimal engine combustion. Too low fuel pressure can lead to lean fuel conditions, causing symptoms like:

- Engine misfires

- Loss of power, especially during acceleration

- Poor fuel economy

- Engine stalling

Conversely, excessively high fuel pressure can also cause problems, though it’s less common. Therefore, accurately checking fuel pressure is a fundamental step in diagnosing various engine performance issues.

Can a Scan Tool Check Fuel Pressure?

The short answer is: it depends on your vehicle and scan tool.

Modern vehicles equipped with electronic fuel injection systems often have a fuel pressure sensor integrated into the fuel rail or fuel line. If your vehicle has this sensor, a capable scan tool can indeed read fuel pressure data from the engine control unit (ECU).

How Scan Tools Read Fuel Pressure:

- OBD-II Port Connection: Scan tools connect to your vehicle’s On-Board Diagnostics II (OBD-II) port, which is standard on most vehicles manufactured since 1996.

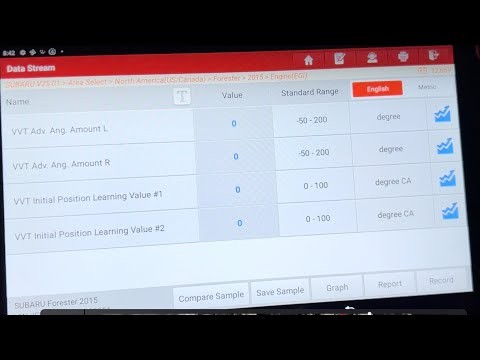

- Live Data Stream: Through the OBD-II port, the scan tool can access a stream of live data from various vehicle sensors, including, potentially, the fuel pressure sensor.

- Parameter Identification (PID): Fuel pressure data is typically accessed using a specific Parameter Identification (PID). Scan tools can display this data in real-time, allowing you to monitor fuel pressure while the engine is running, idling, or under load.

Limitations of Scan Tools for Fuel Pressure:

- Sensor Dependency: Scan tools can only read fuel pressure if the vehicle is equipped with a dedicated fuel pressure sensor that communicates with the ECU. Older vehicles, or some basic fuel systems, may not have this sensor.

- Sensor Accuracy: While generally reliable, sensors can fail or provide inaccurate readings. A scan tool reading is only as accurate as the sensor itself.

- Indirect Readings: Some scan tools might estimate or infer fuel pressure based on other sensor data rather than reading a direct fuel pressure sensor. This inferred data may be less precise than a direct measurement.

- Basic Scan Tools: Entry-level or very basic scan tools might not have the capability to read fuel pressure data, even if the vehicle has a sensor. You’ll need a scan tool that supports live data streaming and the appropriate PIDs.

When to Use a Scan Tool vs. a Manual Gauge

Scan tools are incredibly convenient for quickly checking a wide range of engine parameters, including fuel pressure if available. They are excellent for:

- Initial Diagnostics: Quickly verifying if fuel pressure readings are within the expected range.

- Monitoring Live Data: Observing fuel pressure fluctuations under different engine conditions (idle, acceleration, etc.).

- Checking for Intermittent Issues: Identifying drops or inconsistencies in fuel pressure that might be hard to detect with a static manual gauge test.

However, a manual fuel pressure gauge is often necessary and more reliable in certain situations:

- Vehicles Without Fuel Pressure Sensors: If your vehicle lacks a sensor, a scan tool will be useless for fuel pressure testing. A manual gauge is the only option.

- Verifying Sensor Accuracy: To confirm the reading from a potentially faulty fuel pressure sensor, a manual gauge provides a direct, independent measurement.

- Detailed System Testing: For in-depth diagnosis, especially when troubleshooting fuel delivery problems, a manual gauge allows you to test pressure at specific points in the fuel system, as demonstrated in the original article’s procedure for the Ford Powerstroke diesel engine.

- Testing Mechanical Fuel Pumps: Vehicles with mechanical fuel pumps often require a manual gauge for testing, as they typically don’t have electronic sensors.

Step-by-Step Guide to Check Fuel Pressure Manually (Ford Powerstroke Example)

While scan tools offer digital readings, understanding how to manually check fuel pressure is a valuable skill, especially when dealing with systems like the Ford 7.3L Powerstroke diesel, as outlined in the original document. This procedure uses a manual fuel pressure gauge for direct measurement.

Tools You’ll Need:

- Fuel Pressure Gauge Kit: A 0-160 PSI gauge with appropriate fittings and hoses. For specific applications like the Ford Powerstroke, an M12 1.5 Fuel Port Adaptor might be necessary to connect to the test port.

- Wrenches: To tighten fittings securely.

- Safety Glasses and Gloves: Fuel is flammable and can be under pressure.

- DVOM (Digital Volt-Ohm Meter): To check for fuel pump power (as mentioned in the original notes, though not explicitly for pressure testing, but related to fuel pump diagnosis).

Safety Precautions:

- Work in a well-ventilated area. Fuel vapors are harmful and flammable.

- No smoking or open flames near the fuel system.

- Relieve fuel pressure before disconnecting any fuel lines if possible (refer to your vehicle’s service manual for the proper procedure).

- Catch any spilled fuel with rags and dispose of them properly.

Testing at the Fuel Bowl (Ford Powerstroke Example – 8c from original text):

-

Locate the Fuel Bowl Test Port: On the Ford 7.3L Powerstroke, there’s a designated test port on the fuel bowl.

-

Install the Adaptor and Gauge: Attach the M12 1.5 adaptor (if needed) and connect your fuel pressure gauge to the test port. Ensure all fittings are tight to prevent leaks.

-

Start the Engine: Turn the ignition key to start the engine and let it idle.

-

Read the Pressure: Observe the fuel pressure reading on the gauge at idle. The specification for the fuel bowl test port on this engine is 45 psig minimum (as per the original document, spec 8c).

-

WOT Test (Wide Open Throttle): Safely perform a Wide Open Throttle (WOT) test (in park or neutral, never under driving conditions unless you have a safe testing environment and assistance) and observe the pressure. It should be >42 psig at WOT (spec 8c).

Testing at the Right and Left Heads (Ford Powerstroke Example – 8b from original text):

This procedure, outlined in points 8b and 8d of the original document, involves testing fuel pressure directly at the cylinder heads. This is a more advanced test, potentially indicating issues within the fuel rails or check valves.

-

Locate Test Points: Identify the fuel pressure test points at the front of the right and left cylinder heads.

-

Connect Gauge: Carefully connect your fuel pressure gauge to these test points, one at a time.

-

Road Test (Simulated): The original document mentions “Road Test- engine at full load condition”. In a safe workshop setting, this can be simulated by putting the engine under load in park or neutral, or by having an assistant perform the test while you carefully and safely observe the gauge during a road test. Caution: Secure the hose away from hot components like the turbo and exhaust.

-

Read Pressure: The specification at the head is 45 PSIG minimum at WOT (spec 8b).

Testing the Electric Fuel Pump (Ford Powerstroke Example – 8c from original text):

Testing directly at the electric fuel pump outlet helps isolate pump performance.

- Access Fuel Pump Outlet: Locate the fuel outlet line from the electric fuel pump.

- Connect Gauge: Connect your fuel pressure gauge to this outlet.

- Idle Test: Start the engine and check pressure at idle. For engines built since 1/1/98 (or engine serial #661496), the spec is 51 ± 4.5 PSI @ idle (spec 8c).

- WOT Test: Perform a WOT test (safely) and ensure pressure remains above the 42 PSIG MINIMUM (spec 8c).

Checking for Inlet Restriction (Ford Powerstroke Example – 8d from original text):

If low fuel pressure is suspected, checking for inlet restriction to the fuel pump is crucial. This often requires a vacuum gauge, not just a pressure gauge.

- Connect Vacuum Gauge: Connect a vacuum gauge to the inlet side of the electric fuel pump.

- Measure Vacuum: Start the engine and measure the vacuum. If it exceeds 6 Hg (inches of mercury), there’s likely a restriction between the pump and the fuel tank (spec 8d). Check for blockage in the fuel lines or a clogged fuel filter.

Interpreting Fuel Pressure Readings

- Low Fuel Pressure: Indicates potential issues like a weak fuel pump, clogged fuel filter, fuel pressure regulator malfunction, fuel leaks, or inlet restriction.

- High Fuel Pressure: Less common, but could point to a faulty fuel pressure regulator.

- Fluctuating or Unstable Pressure: May suggest air in the fuel lines, a failing fuel pump, or a regulator problem.

Always compare your readings to the vehicle manufacturer’s specifications for accurate diagnosis.

Conclusion

While scan tools offer a convenient way to check fuel pressure on many modern vehicles, they are not universally applicable. Understanding the capabilities and limitations of your scan tool, and knowing how to perform a manual fuel pressure test with a gauge, are essential skills for any car owner or mechanic. For detailed diagnostics, especially on systems like the Ford Powerstroke diesel, a manual gauge test, as outlined in the original procedure, remains a reliable and necessary approach to pinpoint fuel system problems effectively. By combining the convenience of scan tools with the precision of manual testing, you can ensure accurate fuel pressure diagnosis and keep your engine running smoothly.