VCDS (Vag-Com Diagnostic System) offers a powerful diesel injector test using Measuring Blocks 13 and 15. This test helps assess injector balance and fuel consumption, crucial for diagnosing performance issues in TDI engines. This article delves into interpreting the results of a Vcds Diesel Injector Test, focusing on deviation values and their implications.

Deviations and Their Significance

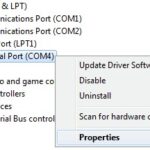

Measuring Block 13 in VCDS displays the injector quantity deviation for each cylinder. These values represent the difference between the actual fuel injected by each injector and the ideal amount. Large deviations indicate an imbalance, potentially causing rough idling, reduced power, and increased emissions. Values exceeding ±2.99 mg/str often signify a failing injector requiring replacement.

While significant deviations typically point to faulty injectors, other factors can contribute to imbalances. A worn camshaft, low compression in a cylinder, or even air in the fuel system can skew the results. Experienced technicians often swap suspected bad injectors with a known good one to isolate the problem. It’s crucial to rule out these other possibilities before condemning an injector. Additionally, a burr can form on the injector body due to contact with the cylinder bore. This burr must be removed before reinstalling an injector to avoid damaging the seals, which can lead to fuel leaks and power loss. Always replace the TTY (Torque-to-Yield) hold-down bolt during injector service.

Injector Pop Pressure and VCDS Readings

The accuracy of the VCDS injector balance test relies on the injectors operating within their specified pressure range. Diesel injectors have a pilot and main injection stage, each with specific pop pressures. A significant drop in these pressures, especially the pilot pressure (from around 220 bar to 170 bar), indicates wear and affects the reliability of the balance test. Injectors with diminished pop pressures may show smaller deviations in VCDS even when significantly worn.

Ideally, injectors should operate within 5% of their target pop pressures for accurate balance testing. While quality diesel fuel and additives can help maintain injector health, reaching 250,000 miles without issues is uncommon. Testing injector pop pressure is essential for a comprehensive diagnosis. If injectors exhibit low pop pressures, simply relying on VCDS balance values can be misleading.

The Limitations of VCDS Injector Testing

While VCDS provides valuable data, it’s essential to understand its limitations. On high-mileage injectors with worn nozzles and reduced pop pressures, Measuring Block 13 may not provide reliable balance information. In such cases, further testing, including pop pressure testing and nozzle pattern analysis, is necessary.

Attempting to rejuvenate old injectors by cleaning or shimming is often time-consuming and rarely cost-effective. Replacing worn injectors with new, properly calibrated units is generally the most reliable solution.

Conclusion

The VCDS diesel injector test is a valuable diagnostic tool, but interpreting the results requires understanding the nuances of injector operation and potential influencing factors. While deviation values offer insights into injector balance, considering factors like pop pressure and overall mileage is crucial for accurate diagnosis and effective repairs. In many cases, especially with high-mileage vehicles, replacing worn injectors offers the most reliable long-term solution.