Experiencing a sudden fuel gauge malfunction can be incredibly frustrating. Imagine driving along, and after a routine oil change reminder reset, your fuel gauge suddenly drops to empty. This is precisely the scenario one car owner faced, leading to a deep dive into automotive diagnostics and the crucial role of scan tools and cluster sweep tests. Let’s explore this real-world problem and understand how a “Cluster Sweep Test Scan Tool” becomes essential in resolving such issues.

The problem began innocently enough. After resetting the oil change reminder in the Driver Information Center (DIC), the car immediately threw codes, and the fuel gauge plummeted to empty. Despite replacing both fuel senders and the fuel pump – common culprits in fuel gauge issues – the problem persisted. Basic wiring checks were performed, confirming continuity between the fuel tank and the Powertrain Control Module (PCM). Adding fuel confirmed the pump was working, yet the gauge remained stubbornly unresponsive.

Even after clearing the diagnostic trouble codes (DTCs), the fuel gauge would only flicker momentarily before dropping back to zero, accompanied by the re-emergence of error codes. A friend’s scan tool finally provided a crucial clue: the fuel gauge failed a gauge sweep test. This test, often overlooked, is a vital function of modern scan tools and can pinpoint issues within the instrument cluster itself.

The scan revealed a series of codes across different modules:

- ECM P2067: Fuel Level Sensor 2 Circuit Low Voltage

- TCICM U1804: Lost Communication with EBCM

- EBCM C0242: Brake Pressure Switch Circuit Low

- SCM U0073: Control Module Communication Bus Off

- SCM U0100: Lost Communication With ECM/PCM

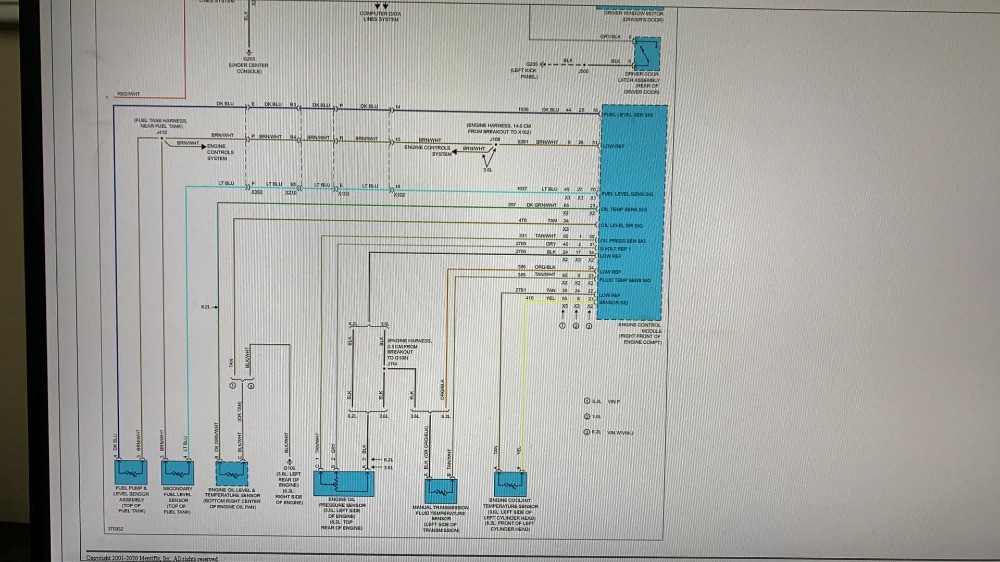

These codes, while seemingly diverse, hinted at a potential communication issue within the vehicle’s network, possibly affecting the instrument cluster’s ability to correctly interpret fuel level data. The P2067 code directly points to a fuel level sensor circuit problem, but the sweep test failure suggested the issue might not be solely with the sensor itself, but with the gauge’s response within the cluster.

To understand the diagnostic path forward, let’s delve into the official diagnostic procedure for fuel gauge malfunctions, particularly when DTCs like P0461-P0464 or P2066-P2068 are present. These codes are directly related to fuel level sensor performance and circuit issues.

The diagnostic instructions emphasize a systematic approach, starting with a Diagnostic System Check. Crucially, it highlights verifying the “Fuel Level Sensor parameters” using a scan tool. This involves checking if the voltage readings from the fuel level sensors are within the expected range (0.5-3.5V) and if they change as fuel level changes. If these parameters are incorrect, it points towards circuit or sensor issues.

However, if the sensor parameters are within range, the next critical step is to “verify that all fuel level gauge sweeps when performing the scan tool Instrument Cluster Gauge Sweep test.” This is where the “cluster sweep test scan tool” becomes indispensable. A gauge sweep test is a function available in many automotive scan tools that commands the instrument cluster to cycle all its gauges (fuel, temperature, speedometer, etc.) from minimum to maximum and back. This test verifies the gauge’s mechanical and electrical functionality.

If the fuel level gauge fails to sweep during this test, as in our initial scenario, the diagnostic procedure directly suggests: “Replace the P16 instrument cluster.” This indicates that the problem likely resides within the instrument cluster itself, not necessarily in the fuel sensors or wiring, assuming those have been checked and are functioning correctly.

The diagnostic process also includes detailed circuit system testing. This involves checking for shorts to ground, opens, shorts to voltage, and high resistance in the fuel level sensor circuits. These tests are crucial for ruling out wiring problems before concluding that the instrument cluster is faulty. Component testing of the fuel level sensor itself is also outlined, involving measuring resistance across its range of motion to check for smooth operation and correct resistance values (typically 37-43 Ohms minimum and 245-255 Ohms maximum).

[

In conclusion, while fuel gauge problems can stem from faulty sensors or wiring, the “cluster sweep test scan tool” is a powerful diagnostic tool for identifying issues within the instrument cluster itself. In cases where the gauge fails the sweep test, and after ruling out other potential causes through systematic testing, instrument cluster replacement might be the necessary solution. For DIY mechanics and professionals alike, understanding and utilizing the cluster sweep test function on a scan tool is vital for accurate and efficient diagnosis of fuel gauge and other instrument cluster related issues.