Differential Scanning Calorimetry (DSC) is a powerful thermal analysis technique used to characterize the properties of plastic materials. By measuring the heat flow in and out of a sample as a function of temperature, DSC provides valuable insights into a polymer’s behavior, enabling researchers and manufacturers to understand its thermal transitions, crystallinity, and overall quality. This article explores the application of DSC in analyzing plastics, focusing on a case study involving a failed polyethylene terephthalate (PET) food storage container.

Understanding DSC in Polymer Analysis

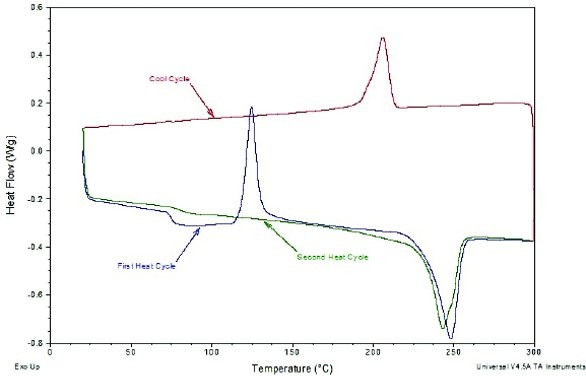

DSC analysis involves subjecting a small sample of plastic to a controlled temperature program while monitoring the heat flow required to maintain a constant heating or cooling rate. This heat flow is directly related to the thermal events occurring within the material, such as glass transition (Tg), melting, crystallization, and curing. Conventional DSC provides overall heat flow data, while Modulated DSC (MDSC) separates the total heat flow into reversing (heat capacity-related) and nonreversing (kinetic-related) components, offering more detailed information.

Case Study: Failed PET Food Container

A failed PET food storage container, exhibiting cracks at feature boundaries after freezer storage, was analyzed using DSC. The cracked sample was compared to a good, uncracked specimen to identify potential causes of failure. Both conventional and Modulated DSC were employed to determine the glass transition temperature, crystallinity, and enthalpic recovery due to aging.

Results and Interpretation

Conventional DSC revealed a lower Tg for the cracked sample (71°C) compared to the uncracked sample (75°C) in the first heat cycle, suggesting differences in processing or storage conditions. MDSC analysis showed a significantly higher enthalpic recovery for the cracked sample (1.7 J/g vs. 0.7 J/g), indicating greater physical aging. Furthermore, the initial crystallinity of the cracked sample was much lower (10 J/g vs. 31 J/g). These findings suggest that the cracked sample had a higher amorphous content, which underwent more significant physical aging, leading to increased brittleness and susceptibility to cracking under stress. The higher amorphous content, coupled with the lower crystallinity in the cracked sample, contributed to its reduced ability to withstand stress, ultimately resulting in failure.

DSC as a Comprehensive Tool

DSC, particularly when combined with other analytical techniques like microscopy and spectroscopy, is invaluable in failure analysis. It allows for the characterization of material properties, identification of processing or storage issues, and investigation of the root causes of product failure. The ability of DSC to measure subtle differences in thermal properties makes it particularly useful in understanding the behavior of complex polymer systems. In this case, DSC played a crucial role in revealing the relationship between crystallinity, physical aging, and the failure of the PET container.

Conclusion

Differential scanning calorimetry is a versatile analytical tool for characterizing plastics and investigating material failures. By providing insights into thermal transitions, crystallinity, and aging behavior, DSC allows researchers to understand the underlying causes of product failure and optimize material performance. The case study of the PET food container demonstrates the power of DSC in revealing the impact of processing, storage, and material properties on product durability.