Your cart is currently empty!

Mastering TDI Timing with VCDS: A Comprehensive Guide

Understanding and adjusting TDI timing is crucial for optimal engine performance and fuel efficiency. This guide delves into the intricacies of using VCDS (Vag-Com Diagnostic System) for TDI timing adjustments, providing valuable insights for car owners, repair shops, and technicians alike. Whether you’re troubleshooting a rough idle or aiming for peak performance, mastering TDI timing with VCDS is an essential skill. Let’s explore how VCDS can empower you to fine-tune your TDI engine. You can use VCDS to check your injector timing, as explained on the VCDS injector timing page.

Precise TDI timing is the cornerstone of a smooth-running and efficient diesel engine. Incorrect timing can lead to a plethora of issues, ranging from poor fuel economy and excessive smoke to rough idling and even engine damage. VCDS provides a powerful interface for diagnosing and correcting these issues, giving you granular control over your TDI engine’s timing.

Understanding the Importance of TDI Timing

Timing in a TDI engine refers to the precise synchronization of fuel injection with the piston’s position in the cylinder. This synchronization is critical for efficient combustion. When the timing is off, even slightly, the combustion process becomes less efficient, leading to reduced power, increased emissions, and potential engine damage over time.

Using VCDS for TDI Timing Adjustments

VCDS transforms your computer into a powerful diagnostic tool, allowing you to access and modify various engine parameters, including TDI timing. The software’s intuitive interface and comprehensive data logging capabilities make it an invaluable asset for anyone working on TDI engines.

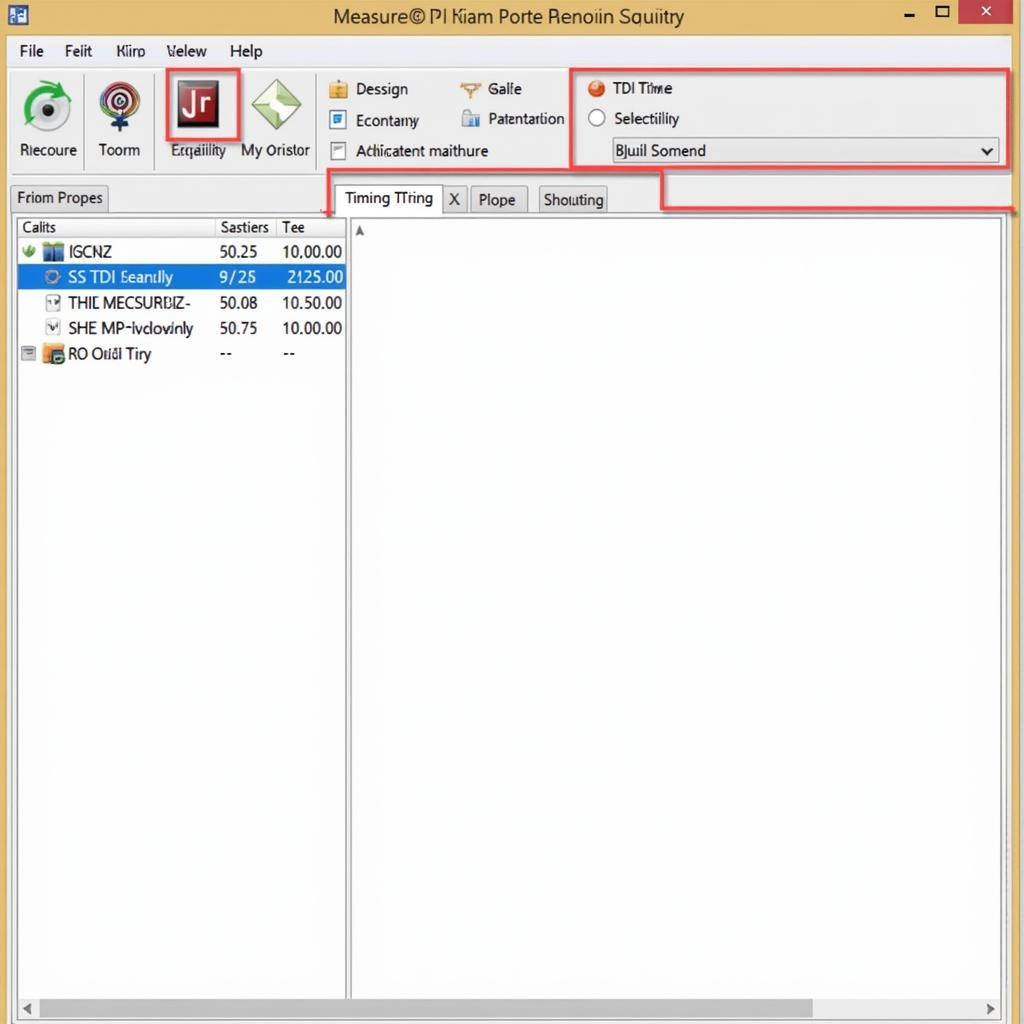

Accessing TDI Timing Settings in VCDS

Connecting your VCDS interface to your car’s OBD-II port is the first step. After establishing communication, navigate to the engine control module and select the “Measuring Blocks” function. Here, you’ll find a wealth of data related to your engine’s performance, including the crucial timing values. For more detailed information on TDI measuring blocks within VCDS, you might find the resource on VCDS TDI measuring blocks helpful.

Adjusting TDI Timing with VCDS

Adjusting TDI Timing with VCDS

Interpreting TDI Timing Values

Understanding the displayed values is crucial for making informed adjustments. VCDS typically presents timing data in degrees before or after top dead center (TDC). These values represent the precise moment when fuel is injected into the cylinder. Comparing these values to the manufacturer’s specifications allows you to identify any deviations and make the necessary corrections.

Making Adjustments with VCDS

Once you’ve identified a timing issue, VCDS allows you to make precise adjustments. The software provides input fields where you can enter the desired timing values. After confirming the changes, VCDS communicates with the engine control module, adjusting the injection timing accordingly.

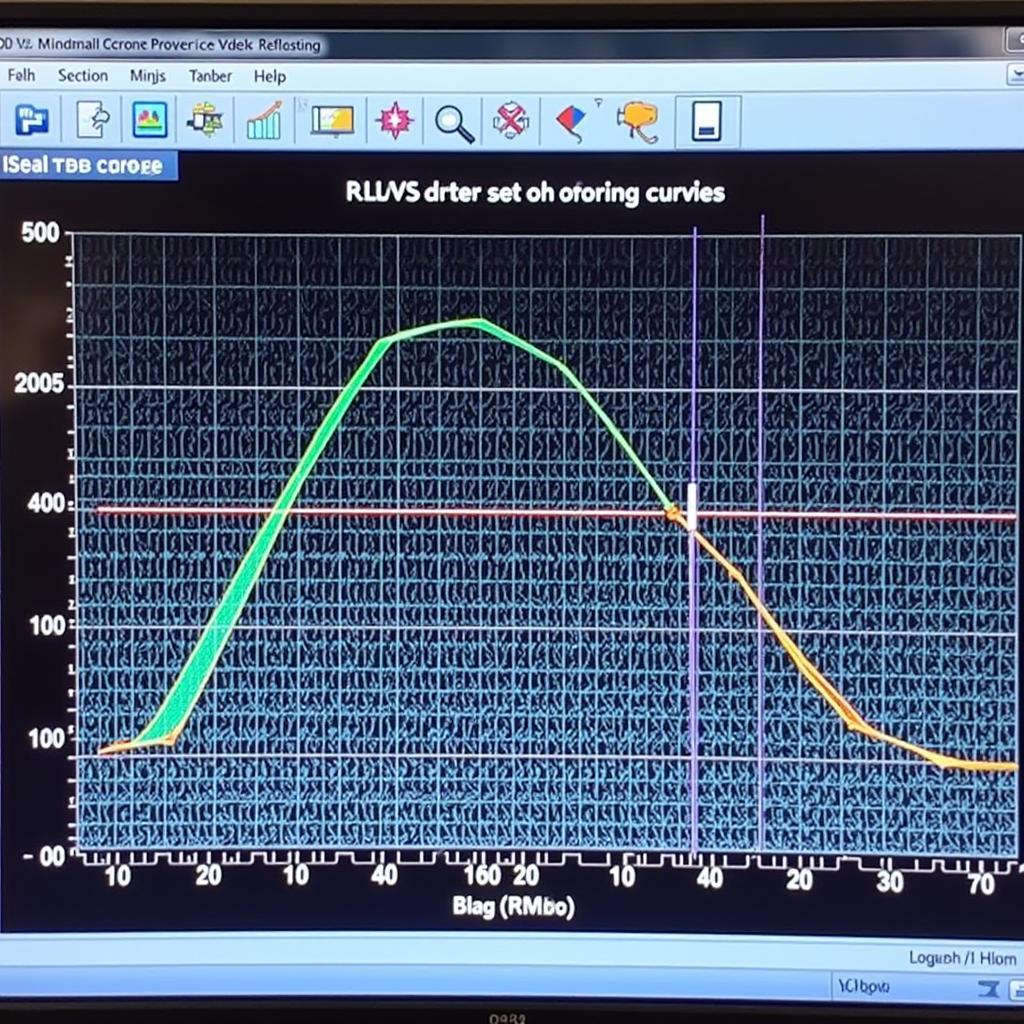

Analyzing TDI Timing Graph in VCDS

Analyzing TDI Timing Graph in VCDS

Common TDI Timing Problems and Solutions

Several factors can contribute to TDI timing issues. Worn timing belts, faulty camshaft position sensors, and even software glitches can all disrupt the precise synchronization required for optimal performance. VCDS allows you to pinpoint the root cause of these issues and implement the appropriate solution.

TDI Timing Belt Issues

A worn or stretched timing belt can significantly impact timing accuracy. VCDS can help diagnose this issue by monitoring timing fluctuations. If the timing varies erratically, a worn timing belt is a likely culprit.

Camshaft Position Sensor Problems

A malfunctioning camshaft position sensor can provide inaccurate timing information to the engine control module. VCDS can detect this issue by monitoring the sensor’s output and comparing it to expected values.

Fine-Tuning TDI Timing for Performance

While correcting timing issues is essential, VCDS also allows for fine-tuning TDI timing to optimize performance. By carefully adjusting the timing within safe parameters, you can achieve improved fuel efficiency, smoother running, and even a slight increase in power output. However, it’s crucial to consult the manufacturer’s specifications and exercise caution when making such adjustments. Improperly adjusted timing can have detrimental effects on engine longevity.

You may find valuable information regarding VCDS FTDI interfaces, which are commonly used with this software, at VCDS FTDI.

Conclusion

Mastering TDI timing with VCDS is an invaluable skill for anyone working on these engines. The software’s diagnostic capabilities, coupled with its ability to make precise adjustments, empower you to optimize your TDI engine’s performance, fuel efficiency, and longevity. By understanding the intricacies of TDI timing and utilizing VCDS effectively, you can ensure your TDI engine runs smoothly and efficiently for years to come. Connect with us at +1 (641) 206-8880 and our email address: vcdstool@gmail.com or visit our office at 6719 W 70th Ave, Arvada, CO 80003, USA for further assistance with your TDI timing vcds needs.

by

Tags:

Leave a Reply