Your cart is currently empty!

Mastering VCDS Measure Blocks: A Comprehensive Guide

VCDS Measure Blocks are a powerful diagnostic tool for understanding the inner workings of your Volkswagen, Audi, Seat, or Skoda vehicle. They provide real-time data from various sensors and control modules, allowing you to pinpoint the root cause of automotive issues. This guide will delve into the world of VCDS Measure Blocks, equipping you with the knowledge to interpret data and effectively troubleshoot problems.

Understanding how to use VCDS Measure Blocks is crucial for any car owner, mechanic, or automotive technician working with VAG vehicles. From diagnosing a simple misfire to troubleshooting complex electronic issues, the ability to interpret these data streams can save you valuable time and money. Whether you’re a seasoned professional or just starting, this comprehensive guide will provide you with the essential information you need. Similar to the process of using vcds instruments security access, accessing and interpreting measure blocks requires a systematic approach.

What are VCDS Measure Blocks?

VCDS Measure Blocks are essentially sets of data points representing various parameters within your vehicle’s systems. Each block contains a specific group of values, such as engine speed, coolant temperature, or fuel pressure. These values are constantly updated, providing a dynamic view of the system’s performance. Think of it like looking under the hood while the engine is running, but instead of seeing mechanical parts, you’re seeing the digital representation of their activity.

How to Access VCDS Measure Blocks

Accessing VCDS Measure Blocks is straightforward. First, connect your VCDS interface to your vehicle’s OBD-II port and launch the VCDS software. Select the appropriate control module for the system you want to diagnose, then navigate to the “Measuring Blocks” function. Each control module has its own set of measure blocks, so knowing which module to access is crucial.

Interpreting the Data

Interpreting the data within VCDS Measure Blocks requires an understanding of the specific parameters being measured. The VCDS software provides labels for each data point, indicating what it represents. However, knowing the expected ranges and how different parameters interact is essential for accurate diagnosis. For instance, a high coolant temperature combined with low engine speed might suggest a cooling system malfunction.

“Understanding the context of each data point within a measure block is crucial for accurate diagnosis,” says John Miller, a seasoned automotive diagnostician with over 20 years of experience. “Don’t just look at individual values; consider the relationships between them.”

Common Uses of VCDS Measure Blocks

VCDS Measure Blocks can be used for a wide range of diagnostic tasks, including:

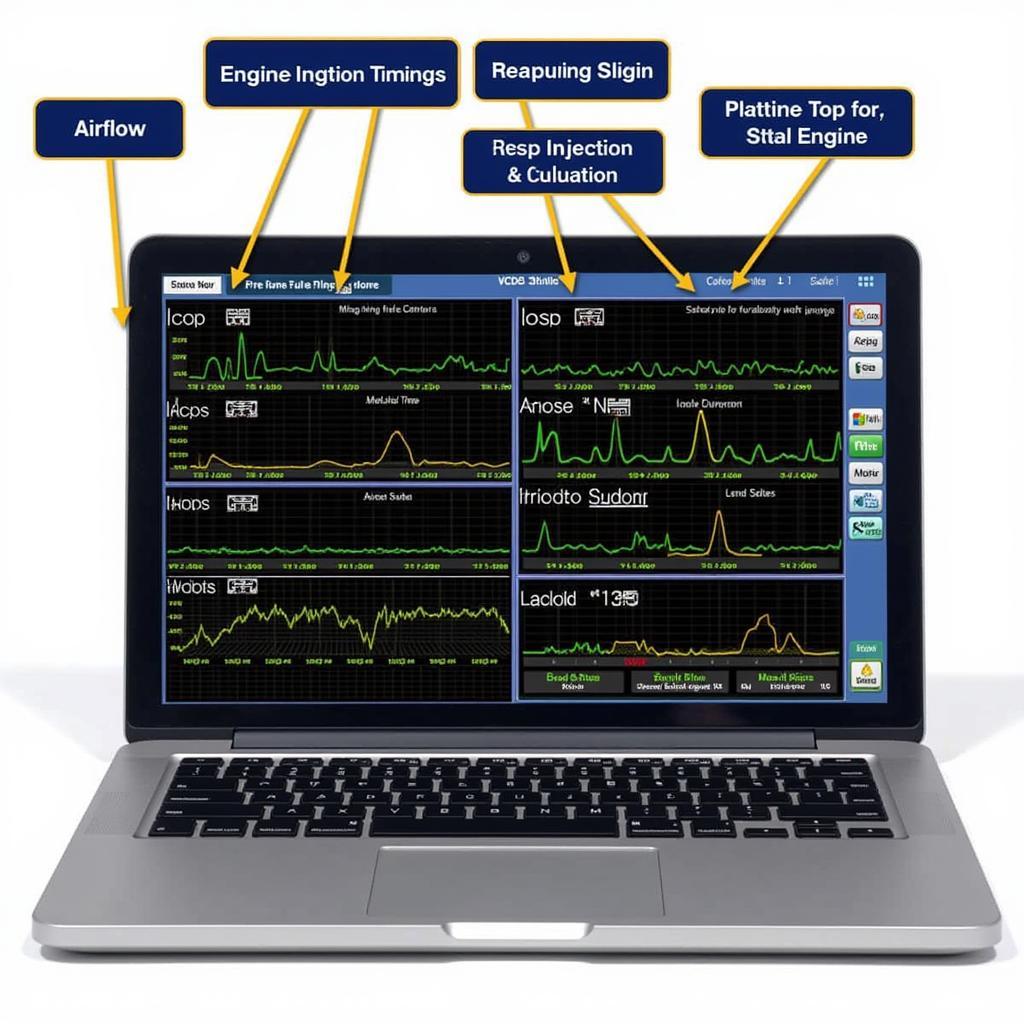

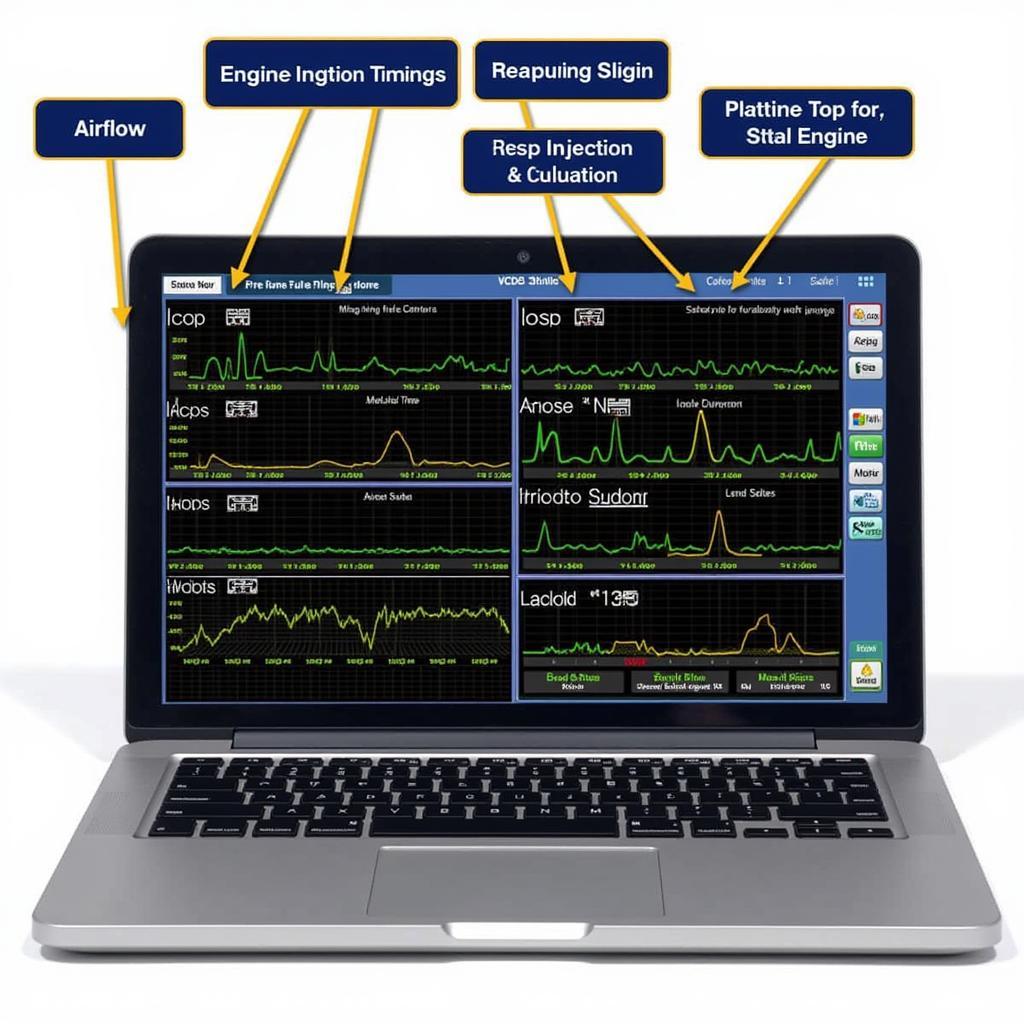

- Engine Performance: Analyzing parameters like ignition timing, fuel injection duration, and airflow can help identify misfires, poor fuel economy, and other performance issues.

- Transmission Diagnostics: Monitoring transmission fluid temperature, shift points, and clutch engagement can reveal problems within the transmission system.

- ABS and ESP Systems: Checking wheel speed sensors, brake pressure, and steering angle sensors can help diagnose ABS and ESP faults.

- Climate Control: Monitoring temperature sensors, actuator positions, and refrigerant pressure can help identify problems with the AC system.

VCDS Measure Blocks for Engine Diagnostics

VCDS Measure Blocks for Engine Diagnostics

Tips for Effective Use of VCDS Measure Blocks

- Consult the Vehicle’s Service Manual: The service manual provides detailed information on the specific measure blocks available for your vehicle and their expected values. This is your bible for understanding the intricacies of your vehicle’s systems. This is similar to checking the vcds check dpf status for diesel particulate filter issues.

- Log Data During a Test Drive: Logging data while driving allows you to capture dynamic changes in parameters, which can be helpful in diagnosing intermittent issues. Just as checking the egr valve test vcds helps diagnose EGR issues, logging data provides valuable insights into system behavior under various conditions.

“Logging data during a test drive is often the key to unlocking the mystery of intermittent problems,” explains Maria Sanchez, a certified automotive technician and VCDS expert. “It provides a real-world view of how the system performs under different driving conditions.”

Advanced VCDS Measure Block Techniques

For more advanced diagnostics, you can use VCDS to:

- Compare Actual vs. Expected Values: This can help identify discrepancies between what the sensors are reporting and what the control module expects.

- Activate Output Tests: Activate components like relays and actuators to test their functionality.

- Adaptations: Modify certain control module settings to fine-tune system performance. Much like understanding the vcds 16-steering wheel status malfunction 0010, adapting modules can resolve specific issues.

Conclusion

VCDS Measure Blocks are an invaluable tool for anyone working with VAG vehicles. By understanding how to access and interpret these data streams, you can effectively diagnose and resolve a wide range of automotive problems. From basic engine diagnostics to complex electronic issues, mastering VCDS Measure Blocks empowers you to take control of your vehicle’s maintenance and repairs. For personalized assistance with VCDS diagnostics or for information on specific measure blocks like the 2001 jetta vr6 2.8 vcds measure blocks for timing, connect with us at +1 (641) 206-8880 and our email address: vcdstool@gmail.com or visit our office at 6719 W 70th Ave, Arvada, CO 80003, USA. Our team at vcdstool is ready to help you unlock the full potential of VCDS.

by

Tags:

Leave a Reply