Your cart is currently empty!

Mastering VCDS PD Timing Check: A Comprehensive Guide

Understanding and interpreting the VCDS PD timing check is crucial for diagnosing and resolving performance issues in your TDI engine. This guide will delve into the intricacies of this essential diagnostic tool, providing you with the knowledge to pinpoint and rectify timing-related problems effectively. We’ll cover everything from understanding the basics of pump-düse (PD) timing to interpreting VCDS readings and implementing corrective measures.

As modern diesel engines become increasingly complex, diagnostic tools like VCDS (Vag-Com Diagnostic System) have become indispensable for both professional mechanics and DIY enthusiasts. Among the many parameters VCDS can analyze, the PD timing check stands out as a vital indicator of engine health and performance, particularly for vehicles equipped with the pump-düse injection system. You can even use VCDS to check if car is tuned vcds.

What is VCDS PD Timing Check?

The VCDS PD timing check essentially measures the synchronization between the camshaft and the pump-düse injection units. Proper timing ensures that fuel is injected into the cylinders at the precise moment for optimal combustion. Incorrect timing can lead to a range of issues, from reduced fuel efficiency and power loss to excessive smoke and even engine damage.

Why is PD Timing Important?

Accurate PD timing is paramount for maximizing engine efficiency, performance, and longevity. When the timing is off, even slightly, the engine’s combustion process is disrupted. This disruption can manifest in several ways, impacting both the performance and lifespan of your engine.

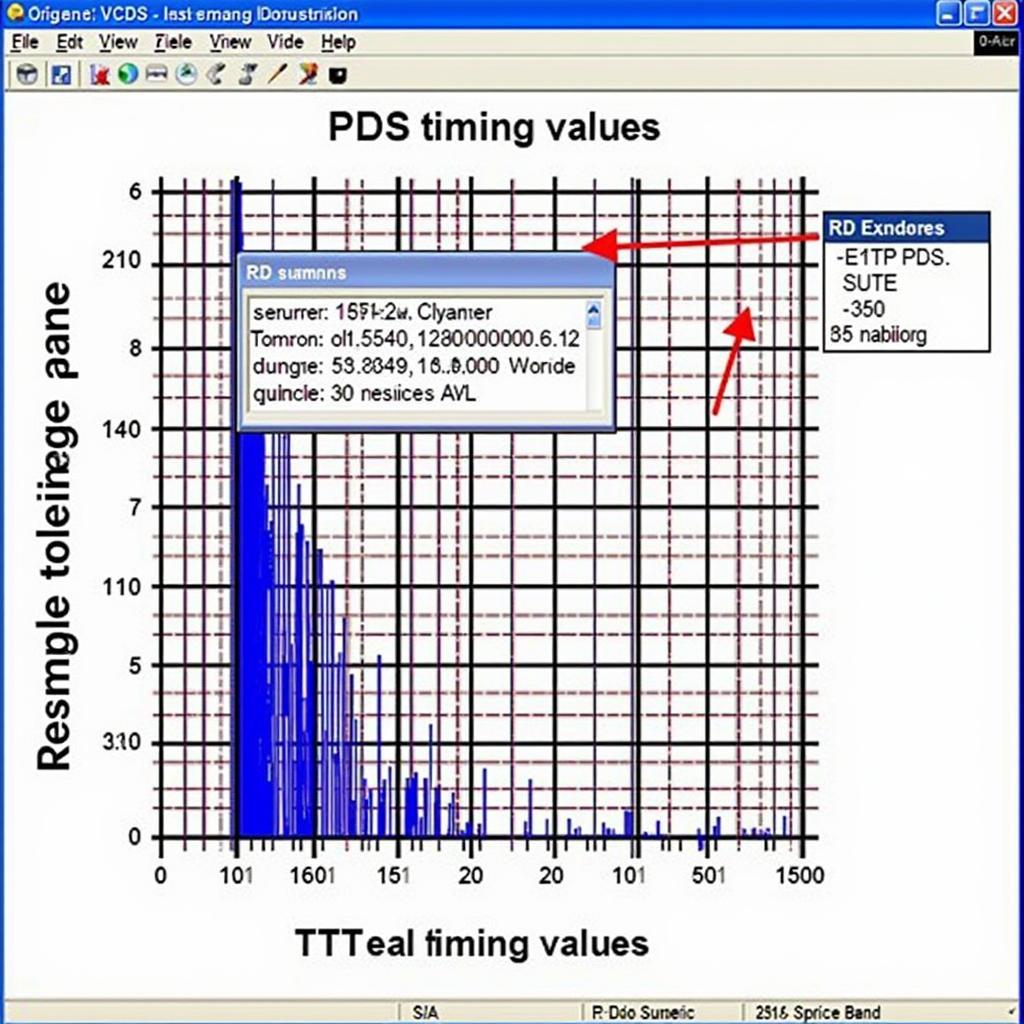

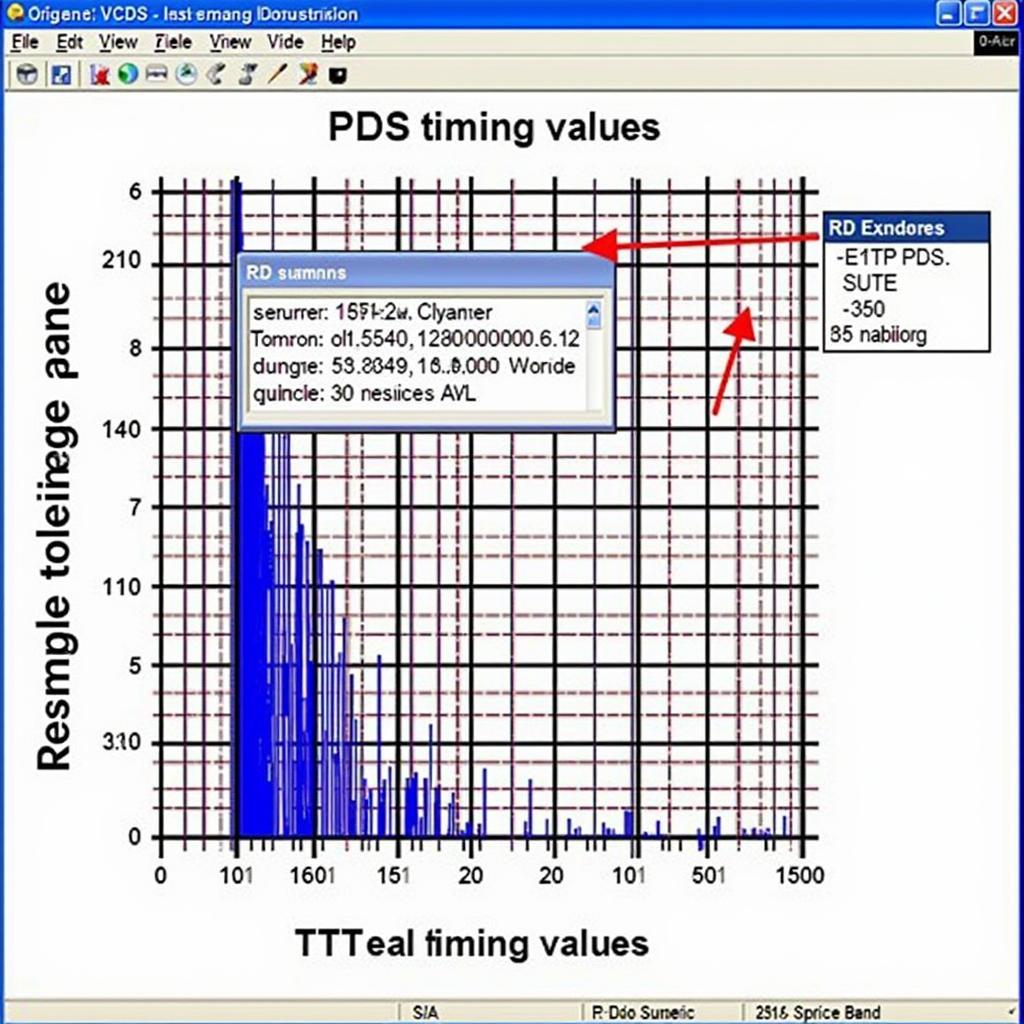

VCDS PD Timing Check Graph Display

VCDS PD Timing Check Graph Display

Imagine a perfectly choreographed dance. If one dancer is out of sync, it disrupts the entire performance. Similarly, if the fuel injection timing is off in your engine, it disrupts the precise combustion process, leading to suboptimal performance and potential long-term damage.

Performing a VCDS PD Timing Check

Before diving into the process, ensure your VCDS software and cable are up-to-date. Connect the cable to your vehicle’s OBD-II port and launch the VCDS software. Navigate to the “Engine” module, then “Measuring Blocks.” Select the appropriate measuring block group for PD timing, which varies depending on your specific engine code.

Interpreting the Results

The VCDS display will show the timing values for each cylinder. These values are typically displayed in milliseconds or degrees of crankshaft rotation. The ideal timing values will vary based on your engine code; consult your vehicle’s service manual for the specific specifications. Significant deviations from these specifications indicate a timing issue. You can also check your vcds torsion value.

“Consistent and accurate PD timing is the cornerstone of a healthy TDI engine,” says John Miller, a seasoned automotive engineer with over 20 years of experience. “Neglecting this crucial aspect can lead to a cascade of problems down the line.”

Common Causes of Incorrect PD Timing

Several factors can contribute to incorrect PD timing. These include:

- Worn camshaft or camshaft lobes

- Faulty camshaft position sensor

- Incorrectly installed timing belt

- Issues with the fuel injection pump

- Problems with the pump-düse units themselves

Troubleshooting and Corrective Measures

Once you’ve identified a timing issue, the next step is to pinpoint the root cause. A thorough inspection of the components mentioned above is crucial. Depending on the diagnosis, corrective measures may involve replacing worn parts, adjusting the timing belt, or even overhauling the fuel injection system. You can find more information related to specific models, such as volkswagen jetta vcds and vw passat vcds.

“Remember, addressing timing issues promptly is key to preventing further damage and ensuring the long-term health of your engine,” advises Maria Sanchez, a certified master technician. “Don’t hesitate to seek professional help if you’re unsure about any aspect of the diagnostic or repair process.”

Conclusion

The VCDS PD timing check is an invaluable tool for maintaining the performance and longevity of your TDI engine. By understanding how to perform and interpret this check, you can identify and address timing-related problems before they escalate into major issues. Regularly checking your PD timing using VCDS will help ensure your engine runs smoothly and efficiently for years to come. For further assistance or personalized guidance, feel free to connect with us at +1 (641) 206-8880 and our email address: vcdstool@gmail.com or visit our office at 6719 W 70th Ave, Arvada, CO 80003, USA. You might also be interested in learning more about vcds sample rate.

by

Tags:

Leave a Reply