Building Information Modeling (BIM) is transforming industries worldwide, offering a comprehensive methodology that spans the entire lifecycle of structures, from initial design and construction to ongoing operations and maintenance. BIM integrates geometric and spatial data with extensive databases, housing critical information on materials, dimensions, and system components. This centralized database serves as a robust foundation for informed decision-making, enhancing coordination and efficiency across all project stakeholders.

Concurrently, Scan to BIM is emerging as a pivotal process, driven by the increasing adoption of BIM by organizations and regulatory bodies implementing stricter BIM mandates. This technology is particularly invaluable for renovations and upgrades of existing automotive repair facilities, many of which lack accurate digital blueprints. Scan to BIM bridges this gap, significantly streamlining planning, coordination, and cost management in automotive repair and modification projects.

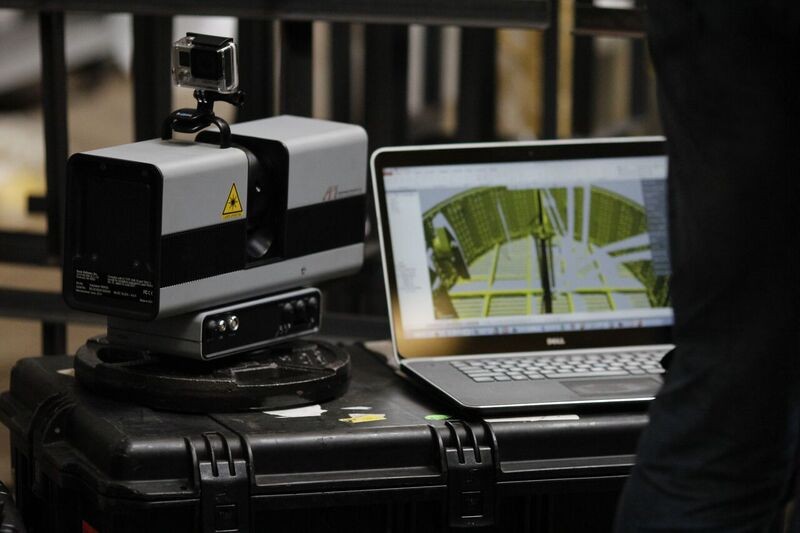

This article explores the diverse array of 3d Laser Scanning Tools utilized in Scan to BIM workflows within the automotive repair sector. We will detail their capabilities, applications, and how they are reshaping automotive repair and customization processes.

Understanding Scan to BIM in Automotive Repair

Scan to BIM represents a cutting-edge workflow within the architecture, engineering, and construction (AEC) industry, and its principles are now being effectively applied to the automotive repair and customization sector. It leverages advanced 3D scanning technologies to capture the precise dimensions and geometries of existing automotive structures, from body shops to custom garages, converting these physical spaces into intelligent BIM models.

This process enables accurate digital documentation of existing automotive facilities, ensuring seamless alignment with contemporary planning and documentation methods. The adoption of Scan to BIM in automotive contexts results in considerable time savings and fosters more efficient and effective collaboration throughout the entire lifecycle of an automotive facility or customization project.

Technologies such as terrestrial and mobile LiDAR scanners are deployed to meticulously scan automotive spaces. These tools generate detailed point cloud datasets, which serve as the foundational data for constructing precise and functional BIM models tailored to automotive repair and modification needs.

Terrestrial Laser Scanners for Automotive Spaces

Terrestrial laser scanners, often referred to as static laser scanners, are recognized as premier tools in 3D capture technology, playing a crucial role in modern surveying and increasingly in the automotive industry for facility digitization.

These scanners are adept at digitizing intricate automotive environments with exceptional detail and speed. Typically mounted on tripods, terrestrial scanners employ a rotating laser to capture extensive areas from stationary positions. In automotive repair, this can include entire body shops, service bays, or vehicle storage areas.

The output is a highly accurate point cloud, forming the basis for BIM models, CAD drawings, and various applications requiring precise measurements and comprehensive documentation of physical automotive spaces. This precision is vital for planning automotive equipment layouts, optimizing workflow, and ensuring accurate modifications and repairs.

API HemiScan for Automotive Applications

API HemiScan 3D laser scanning tool capturing data in an automotive repair environment.

API HemiScan. Source: https://apimetrology.com/hemiscan/

Max. Reach: 70 m

Scan Rate: 1.2 million points/second

Price: on request

The API HemiScan stands out as a robust 3D BIM scanner, ideally suited for both industrial and outdoor automotive applications. Boasting a scan rate of up to 1.2 million points per second and a range of 70 meters, this spherical scanner delivers highly accurate measurements essential for detailed automotive facility modeling. With a resolution of 0.001 mm, it facilitates the creation of high-resolution 3D CAD models, perfect for designing precise automotive repair layouts or custom fabrication setups.

The scan data from the HemiScan is compatible with leading software applications such as PolyWorks®, RapidForm®, Geomagic®, Cyclone®, and RealWorks®. Its durable design and high mobility make the HemiScan well-suited for demanding automotive scanning tasks where precision and reliability are paramount, such as capturing complex automotive assembly lines or detailed vehicle lift installations.

Artec Ray II for Automotive Design and Retrofitting

Artec Ray II terrestrial laser scanner being used in an automotive garage to scan a vehicle for custom part design.

Artec Ray II. Source: https://www.artec3d.com/portable-3d-scanners/laser-ray

Max. Reach: 0.5-130 m

Scan Rate: 2 million points/second

Price: ~ €60,000

The Artec Ray II is a versatile terrestrial 3D laser scanner with a range extending up to 130 meters and an accuracy of less than 1.9 mm at 10 meters. It rapidly generates dense, detailed point clouds in just 1.7 minutes. Equipped with three internal cameras offering 36-megapixel resolution, it captures high-definition color data alongside geometric information, useful for automotive paint shop documentation or custom interior design visualization. The built-in rechargeable batteries provide up to four hours of operation, enhancing its portability for both indoor and outdoor automotive scanning scenarios.

The Artec Ray II supports seamless integration with handheld scanners like the ARTEC Eva, Spider, or Leo. This combination is particularly advantageous for capturing intricate details of vehicles or tight spaces within automotive interiors or engine bays. Data processing is handled by the powerful ARTEC Studio software, enabling users to directly edit scan results and export them for reverse engineering in programs like Geomagic Design X, SolidWorks, or ReCap, critical for automotive part replication or custom modification design.

FARO Focus Premium for Automotive Facility Management

FARO Focus Premium 3D laser scanner deployed in a large automotive warehouse for facility mapping and inventory management.

FARO Focus Premium. Source: https://www.faro.com/

Max. Reach: 70 m, expandable to 350 m

Scan Rate: 2 million points/second

Price: ~ € 40,200

The FARO Focus Premium is engineered for high-performance 3D laser scanning, completing a scan in approximately one minute depending on settings. With a range of 70m, expandable to 350m, and a scanning speed of two million points per second, it is exceptionally efficient for large automotive spaces like dealerships or manufacturing plants.

The FARO Focus Premium streamlines data capture, processing, and team sharing. Scanner control and preliminary data processing are facilitated via the FARO Stream app for Android and iOS, while final data registration is performed using FARO Scene, minimizing office-based processing time. This rapid workflow is ideal for quickly generating as-built documentation of automotive facilities for renovation planning, maintenance scheduling, or digital twin creation.

Teledyne Optech Polaris for Large-Scale Automotive Sites

Teledyne Optech Polaris 3D laser scanner used at a large automotive proving ground for topographic surveying and site analysis.

Teledyne Optech Polaris. Source: https://www.teledyneoptech.com/

Max. Reach: 2,000 m

Scan Rate: 1 million points/second

Price: on request

The Teledyne Optech Polaris is a terrestrial 3D laser scanner renowned for its extensive range and reliability across diverse applications, including large automotive manufacturing sites, proving grounds, and salvage yards. It delivers highly accurate data even in harsh environmental conditions thanks to its weatherproof housing and robust design. The Polaris can be mounted on tripods, platforms, or vehicles, offering versatility for different automotive scanning needs.

Characterized by a wide, customizable field of view, the Polaris can capture large areas or focus on specific segments, essential for mapping expansive automotive facilities or detailed analysis of crash test sites. It boasts a maximum range of 2,000 meters, a 2mm resolution within its measuring range, and an accuracy of 5mm to 100 meters, making it suitable for large-scale automotive projects requiring precise geospatial data.

Leica ScanStation P50 for Hard-to-Reach Automotive Infrastructure

Leica ScanStation P50 3D laser scanner being used to survey elevated automotive infrastructure, such as car park structures.

Leica ScanStation P50. Source: https://leica-geosystems.com/

Max. Reach: more than 1 km

Scan Rate: 1 million points/second

Price: ~ € 35,000

The Leica ScanStation P50 is a high-performance 3D laser scanning solution designed for industry professionals needing to survey inaccessible automotive locations safely and efficiently from a distance, such as elevated parking structures or complex automotive plant rooftops. Its impressive range and ability to deliver high-quality 3D data and HDR imagery enable the capture of large and challenging automotive infrastructure or expansive vehicle storage facilities.

Robust and reliable in extreme conditions, operating from -20 °C to +50 °C with an IP54 rating for dust and water protection, the ScanStation P50 is ideal for diverse automotive environments. Data processing is powered by Leica Cyclone, JetStream, CloudWorx, and the free Leica TruView software suite, integrated with the Cyclone FIELD 360 app for seamless field-to-office data registration. This comprehensive solution supports efficient BIM workflows for complex automotive projects.

Handheld Scanners for Automotive Component and Interior Scanning

Handheld scanners are compact, portable devices designed to capture 3D data from objects and environments with greater flexibility and maneuverability, making them highly valuable in automotive repair for scanning vehicle interiors, components, and intricate details. Their portability allows users to move around vehicles and parts easily, capturing data in complex or hard-to-reach areas within automotive settings. Handheld scanners are ideal for efficient scanning of smaller or detailed automotive objects, often providing immediate data visualization and editing capabilities.

Dotproduct DPI-10 KIT for Automotive Part Replication

Dotproduct DPI-10 KIT handheld 3D scanner being used to scan a car bumper for reverse engineering and replication.

Dotproduct DPI-10 KIT. Source: https://www.dotproduct3d.com/dpi10.html

Max. Reach: 0.6-3.7 m

Scan Rate: Real-time detection

Price: ~ € 3,600

The DotProduct DPI-10 Kit is an advanced handheld 3D imaging system that captures automotive objects and environments in real time. Equipped with a PrimeSense Carmine 1.08 camera and Dot3D™ software, it transforms a Samsung Galaxy S6 or Windows Go tablet into a user-friendly handheld scanner.

Data processing and registration occur directly on the tablet, allowing users to define coordinate systems, register multiple datasets on-site, and take instant measurements. The Dot3D™ software employs advanced SLAM algorithms for real-time 3D reconstruction and localization on the mobile device. This capability is particularly useful in automotive repair for quickly scanning damaged parts for replacement or custom fabrication, or for documenting vehicle modifications.

Intel Realsense D455 KIT for Automotive Interior and Small Component Scanning

Intel Realsense D455 KIT handheld 3D scanner being used to scan a car interior for custom upholstery design.

Intel Realsense D455 KIT. Source: https://store.intelrealsense.com/

Max. Reach: 0.4-4.2 m

Scan Rate: up to 90 fps

Price: ~ € 1,900

The Intel® RealSense™ D455 kit represents the latest advancement in the D400 series, incorporating over a decade of stereo camera technology and customer feedback. Featuring LiDAR technology with an integrated RGB camera and IMU, it enables precise 3D data capture from 0.4 to 4.2 meters.

Complemented by Dot3D™ Pro software, which uses advanced SLAM algorithms, the kit supports real-time point cloud acquisition, processing, and reconstruction on mobile devices. This makes it ideal for automotive applications requiring detailed scans of interiors, dashboards, or small components for customization or repair.

FARO Freestyle 2.5 for Automotive Interior and Exterior Detailing

FARO Freestyle 2.5 handheld 3D scanner being used to scan the exterior of a car for damage assessment and repair planning.

FARO Freestyle 2.5. Source: https://www.faro.com/

Max. Reach: 0.4-10 m

Scan Rate: 220,000 points/second

Price: on request

The FARO Freestyle 2.5 is a handheld 3D scanner designed for rapid, photorealistic 3D data capture and real-time visualization. With a range of 0.4 to 10 meters, the Freestyle 2.5 offers intuitive scanning without requiring additional hardware, as all data is visualized directly on the device.

Delivering high-quality, color 3D data with up to 0.5 mm accuracy, the scanner provides haptic feedback to ensure scan quality, displayed live on the device. Advanced tracking algorithms support natural scanning movements and seamless integration with professional software like FARO Scene for further analysis. This scanner is well-suited for automotive applications such as documenting vehicle damage for insurance claims, creating digital records of vehicle conditions, or capturing complex surface geometries for custom body work.

Mobile Laser Scanners for Automotive Facility and Large Object Scanning

Mobile laser scanners capture environments while in motion, such as walking through an automotive facility or around a large vehicle. More sophisticated models integrate a measuring head, multiple laser scanners, and panoramic cameras. Position tracking is enhanced with GPS antennas and an IMU (Inertial Measurement Unit). These systems are especially beneficial in automotive for rapidly mapping large spaces or objects.

Metaroom® Scan App for Automotive Workshop Digitization

Metaroom® Scan app being used on an Apple Pro device to scan an automotive repair workshop.

Metaroom Scan app. Source: https://amrax.ai/

Max. Reach: 5 m

Scan Rate: Real-time detection

Metaroom® Scan app: free

Metaroom® Studio Price: from € 79/month

The Metaroom® Scan app is an advanced 3D scanner for Apple Pro devices, utilizing the device’s LiDAR sensor to scan automotive interiors and create detailed 3D models of rooms and spaces. The LiDAR sensor is crucial for capturing spatial dimensions during the scan, while AI-based object recognition enhances accuracy and detail in the digital models. This combination simplifies the scanning process, enabling professionals to create accurate 3D models of automotive workshops, showrooms, or storage facilities.

With the Metaroom®Scan app, users can create comprehensive 3D models of entire automotive buildings by scanning room by room, floor by floor. Individual scans are automatically combined into a cohesive 3D model, providing thorough documentation of the automotive building’s structure. Users can highlight important areas and features, such as service equipment locations or safety installations, which are precisely located in the model. Post-scan, data is cloud-processed into CAD-ready 3D models, enrichable in Metaroom® Studio with additional information and specifications, and exportable in various formats for seamless BIM and CAD software integration.

FARO Orbis for Hybrid Automotive Scanning Applications

FARO Orbis mobile 3D laser scanner being used to quickly map a large automotive manufacturing floor.

FARO Orbis. Source: https://www.faro.com/

Max. Reach: 120 m

Scan Rate: 640,000 points/second

Price: ~ € 47,000

The FARO Orbis merges the advantages of terrestrial laser scanning with mobile SLAM technology, enabling up to ten times faster data acquisition compared to traditional methods in automotive settings.

With a 120-meter range and a 640,000 points-per-second acquisition rate, Orbis delivers both the speed of SLAM and the accuracy of terrestrial scanning, thanks to integrated FARO Flash technology. This hybrid approach is ideal for quickly capturing large automotive environments while maintaining high precision, suitable for creating digital twins of automotive plants or large service centers.

ZEB Horizon for Versatile Automotive Scanning Indoors and Outdoors

ZEB Horizon mobile 3D laser scanner being used outdoors at an automotive testing facility.

ZEB Horizon. Source: https://www.faro.com/

Max. Reach: 100 m

Scan Rate: 300,000 points/second

Price: on request

The ZEB Horizon and ZEB Horizon RT are mobile laser scanners from GeoSLAM, designed for both indoor and outdoor automotive applications. With a range of up to 100 meters, these devices are perfect for data collection in large, open automotive spaces and GPS-challenged environments, such as underground parking garages or dense vehicle storage areas.

Operation is intuitive, and data evaluation occurs on-site, allowing flexible use on drones, vehicles, or on foot. Capturing 300,000 points per second with up to 6 mm accuracy, the scanner includes GeoSLAM Connect and GeoSLAM Draw software for automatic registration and rapid data evaluation, ideal for quick automotive site assessments or accident scene documentation.

The following table provides a comparative overview of the key features of the discussed scanners:

| Scanner | Max. Reach | Scan Rate (points/second) | Price | Special Features for Automotive Use |

|---|---|---|---|---|

| FARO Focus Premium | up to 350 m | up to 2 Mio. | €40,200 | High-Speed SSD, robust for shop floors, GeoSLAM for dynamic environments |

| TELEDYNE OPTECH POLARIS | up to 2,000 m | 1 Mio. | Unknown | Long range for large sites, GPS-poor environment capability for garages |

| ARTEC Ray II | up to 130 m | up to 1.2 Mio. | €60,000 | Portable, high-resolution CAD for vehicle design, integrates with handhelds for detail |

| DotProduct DPI-10 Kit | 0.6 – 3.7 m | Real-time | €3,600 | Handheld, for vehicle interiors & parts, on-site processing |

| Intel® RealSense™ D455 Kit | 0.4 – 4.2 m | up to 90 fps | €1,900 | RGB camera for texture, LiDAR for accuracy, component & interior detail |

| FARO Freestyle 2.5 | 0.4 – 10 m | 220,000 | Unknown | Portable, color data for damage assessment, real-time feedback |

| ZEB Horizon / ZEB Horizon RT | up to 100 m | 300,000 | Unknown | Mobile for facilities, UAV mountable for rooftops, fast assessment |

| FARO Orbis | up to 120 m | 640,000 | €47,000 | Hybrid for large facilities, fast & accurate for digital twins |

| Leica ScanStation P50 | more than 1 km | 1 Mio. | €35,000 | Long-range, robust for infrastructure, extreme weather ready |

| Metaroom® Solution | 10 m | Real-time | from €79/month | Cost-effective app, Apple Pro devices, easy workshop digitization |

| FARO Focus S70 | up to 70 m | 976,000 | Unknown | Accurate, fast, precise measurements for detailed documentation |

Feature overview of 3D scanners and their automotive applications.

Conclusion: The Future of Automotive Repair with 3D Laser Scanning Tools

The integration of 3D laser scanning technologies has significantly revolutionized Building Information Modeling (BIM) and is now transforming the automotive repair industry. These “Scan to BIM” technologies enable precise capture of existing automotive structures, from repair shops to custom garages, providing essential data for planning, renovation, and maintenance. This is particularly beneficial for older automotive facilities lacking digital documentation, creating a precise foundation for improved coordination and cost management.

While many high-performance laser scanners are positioned in the higher price segment and are typically employed by professional surveyors and large automotive manufacturers, more accessible and powerful alternatives are emerging. Mobile laser scanning solutions, such as the Metaroom® system, offer a cost-effective yet robust option. Metaroom’s user-friendly and flexible system allows for detailed 3D model creation of automotive facilities using standard Apple Pro devices, room by room. This approach is not only efficient but also reduces costs by eliminating the need for specialized hardware. Seamless integration of captured data into leading BIM software positions Metaroom as a valuable tool for automotive professionals across all phases, from initial planning to facility renovation and customization.

In conclusion, modern 3D laser scanning tools are an indispensable asset for advancing building information modeling within the automotive sector. They substantially simplify the capture process and optimize subsequent planning and construction phases in automotive facility projects. These technological advancements enhance accuracy and expand BIM capabilities, leading to more efficient, cost-effective, and precise automotive repair and customization projects.